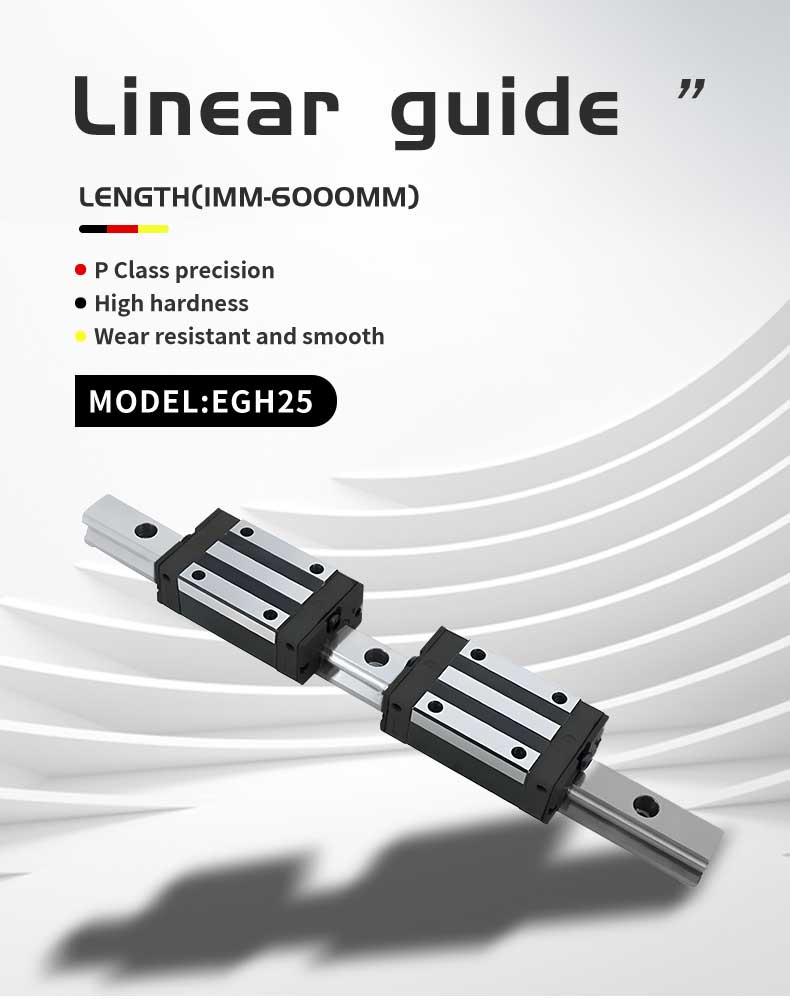

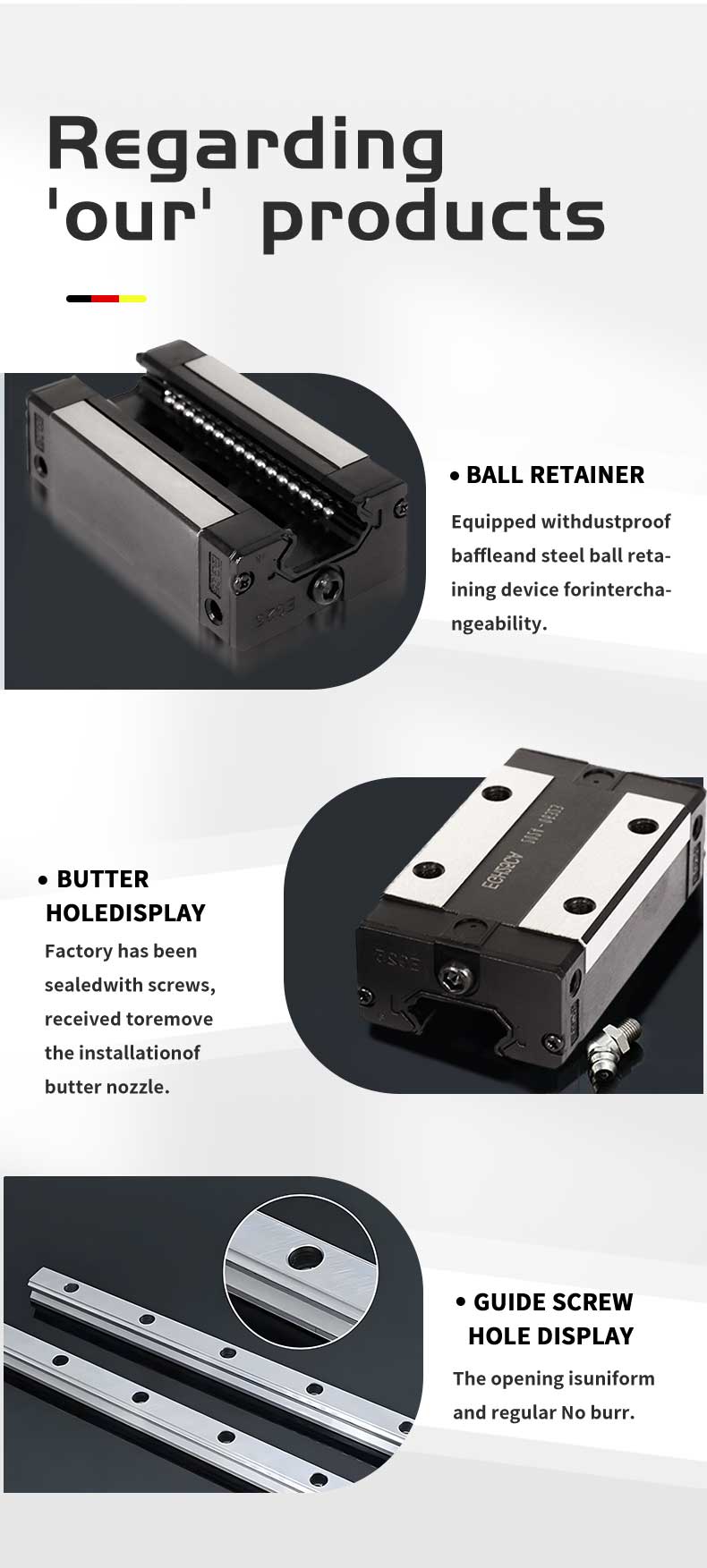

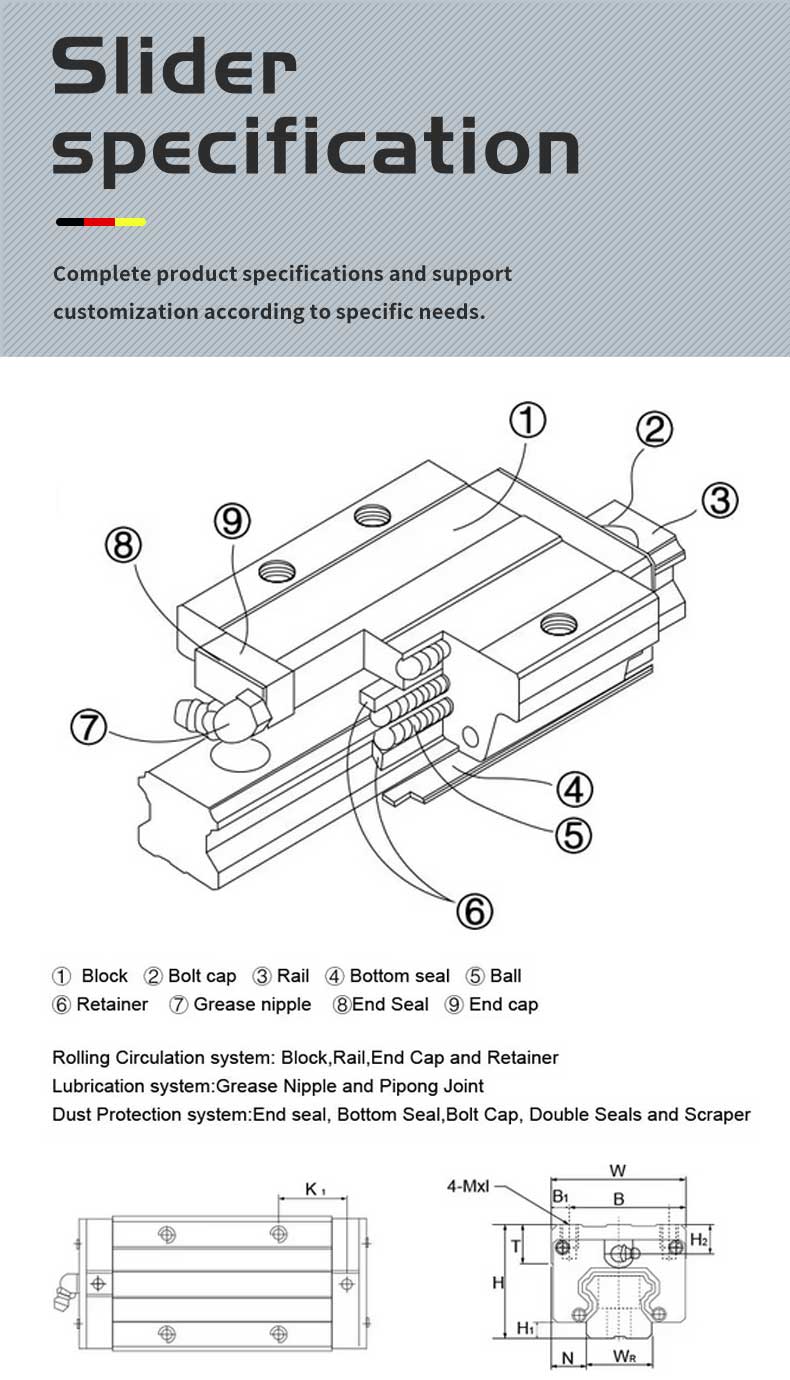

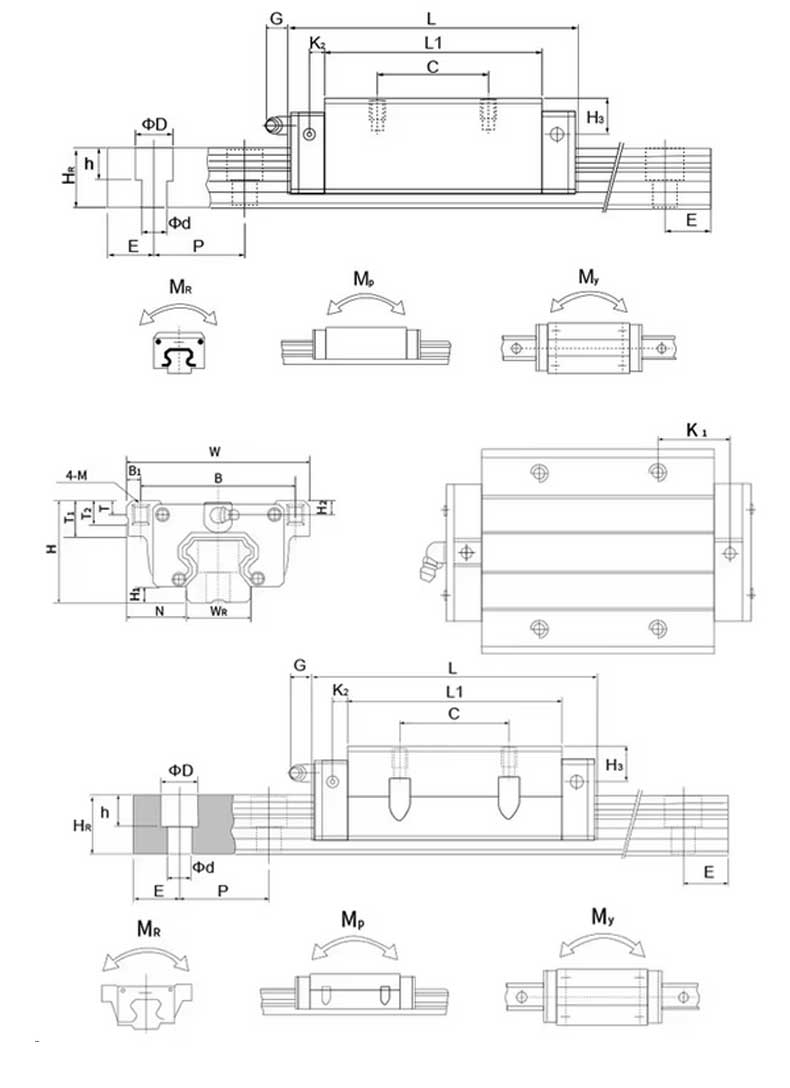

High-Precision Linear Guide Rail With Block Slider is consisted of rail, block, rolling elements, retainer, recirculator, end seal etc. By using the rolling elements, such as balls or rollers between the rail and block, the high precision linear guide can achieve high precision linear motion. The ball bearing linear guide is divied to flange type and square type without flange.or Seal type block, Standard type block, Double bearing type block, Short type block. Also,linear block is divided to high load capacity with standard block lenth and ultra high load capacity with longer block length.

In modern industrial equipment, vertical linear guide rails and ball bearing linear guides are widely used in a variety of scenarios that require precise motion control. High precision linear guide systems are not only able to carry heavy loads, but also maintain smoothness and accuracy at high speeds. Therefore, high precision linear guide (high precision linear guide) and precision linear guide (precision linear guide) has become an important technology in automation, robotics and precision machining and other fields.

1. Vertical linear guide (Vertical Linear Guide Rails)

Vertical linear guide is installed in the vertical direction of the guide system, applicable to the need for up and down movement of mechanical devices. Vertical guide rail design must take into account the effect of gravity on the load and slide movement. Therefore, vertical linear guide rails are usually designed with higher rigidity and accuracy to ensure that in vertical applications, the load can run smoothly along the guideway without lateral deflection. They are commonly used in automatic lifting equipment, precision mechanical devices and other scenarios that require high stability and reliability.

2. Ball Bearing Linear Guide (Ball Bearing Linear Guide)

Ball Bearing Linear Guide utilises the rolling friction of the balls between the guide and the slider to reduce the resistance to movement. The advantage of this design is that it provides an extremely low coefficient of friction while increasing the accuracy and life of the guideway. Ball bearing guideway systems are typically used in high load, high precision and high speed applications such as CNC machine tools and automated assembly lines. Their high load carrying capacity and long service life make them a key component in many industrial equipment.

3. High Precision Linear Guide (High Precision Linear Guide)

High Precision Linear Guide is designed to meet the needs of very high positioning accuracy, and is usually used in scenes that require micron-level precision control. Its precision machining and strict tolerance control enable it to maintain excellent motion accuracy even under high loads. This type of guideway system is widely used in medical equipment, optical instruments and semiconductor manufacturing equipment to ensure high precision and low error during operation.

4. Precision Linear Guide (Precision Linear Guide)

Precision Linear Guide is specially designed for demanding industrial equipment and precision processing equipment with excellent smoothness and repeatability. In the slider and guideway cooperation, precision guide provides higher rigidity and smaller clearance, to ensure the smoothness and accuracy of mechanical movement. Precision guideways can withstand complex multi-axis movements and are suitable for all types of automation and robotics equipment.

In short, the High-Precision Linear Guide Rail With Block Slider system combines vertical linear guide rails, ball bearing linear guide rails, and high-precision and precision guide rails to form a highly stable, accurate and reliable linear motion solution. Widely used in various industrial scenarios, it not only improves productivity, but also significantly extends the service life of the equipment.

Load capacity is determined by dynamic (C) and static (C₀) load ratings. For example: A 6205 deep groove ball bearing has a dynamic load rating of 14 kN, suitable for small motors. For heavy loads, choose tapered roller bearings (e.g., 32208 with C=90 kN). Recommendation: Share your equipment’s load analysis for optimal bearing selection.

Materials: Stainless steel (440C/316) or coatings (nickel plating, DLC). Seals: Double rubber seals (2RS) or PTFE seals. Example: Seawater pumps often use 316 stainless steel bearings with lifelong grease.

Speed limits depend on bearing type and lubrication: Standard 608ZZ ball bearings: ~18,000 rpm. Hybrid ceramic bearings (Si3N4 balls): 30–50% higher speeds. Solution: For high-speed applications, opt for oil lubrication or low-friction design.

Theoretical lifespan: Based on load calculations (see Q1). Real-world factors: Lubrication intervals (e.g., grease replenishment every 100km). Mounting surface flatness (≤0.01mm/m required). Tool: Free lifespan calculation software available.

Must-check: Slider hole spacing (e.g., 45mm×45mm). Rail width (15/20/25mm, etc.). Slider height (impacts machine space). Pro tip: Old slider model numbers are often engraved on the side.

Of course, we provide customized service, including add customers’ logo on the products, customized size of linear guide rail.

It according to the products, we usually can adjust the quantity according to customers’ request.

Invoices are automatically emailed to you when you complete your order. If you did not receive one contact us and provide your order number so we can find your order.

When your order ships you will receive an email with a tracking number which should have an estimated delivery date. Check your spam folder if you do not see it in your inbox. For more information on shipping, please reference our shipping policy.

You can either fill out the contact us form on our website, or head over to our sister website ngsbearing.com and request a quote over there for any product you see here on Bearings Direct. Please note that there will be minimum order quantities.