High-Precision Motorized Linear Guide Slider is in a variety of different options to meet a wide range of customer needs. Available in hardened steel, CK45 material steel, SUJ2 material steel, Aluminium alloy material , inch and metric, Simplicity Shafting maintains the ideal surface finish for linear plain bearings and ball bearings.

Solid round shafting is available in inch sizes from 3/16" thru 4" and metric sizes from 3 mm thru 80 mm

Low frictional linear guide slider

Steel balls are accurately guided by a retainer, so low frictional resistance and stable linear motion can be achieved.

Simple replacement of conventional plain bushings

It is easy to use Linear Bushings instead of conventional plain bushings, because both types are used with a round shaft, and no major redesign is necessary.

Wide variations

For each dimensional series, standard, adjustable clearance and open types are available with and without seals, so the best linear motor guide for the application may be selected.

High Reliability

ERSK linear bearing has very stringent quality control standards covering every production process. With proper lubrication and use,trouble-free operation for an extended period of time is possible.

Smooth Operation

The high efficiency of linear shaft is vastly superior to conventional shaft. The torque required is less than 30%. Linear motion can be easily changed from rotary motion. The linear bearings are moved very smoothly in the linear shaft.

High Durability

Rigidly selected materials, intensive heat treating and processing techniques, backed by years of experience,have resulted in the most durable linear bearings manufactured.

Linear bearings, linear blocks, linear bushing, linear motion units, linear motion slide,linear motor guide

Application

For delicate application in industrial application, machine tool and automation application.

We at Foshan Weierma Bearing Company can offer unrivalled product and application knowledge, we can supply ballscrew products of any size or type to our valued customer.

We place huge importance on our reputation - a reputation that seems to preceed us more and more. This reputation can only grow through good service and quality products so we're committed to expanding our range with nothing but the best products and services and the in-house knowledge to back it all up. Of course, in-house knowledge is vitally important, not just to us, but you as a customer - so we're proud to host some of the best people in the industry.

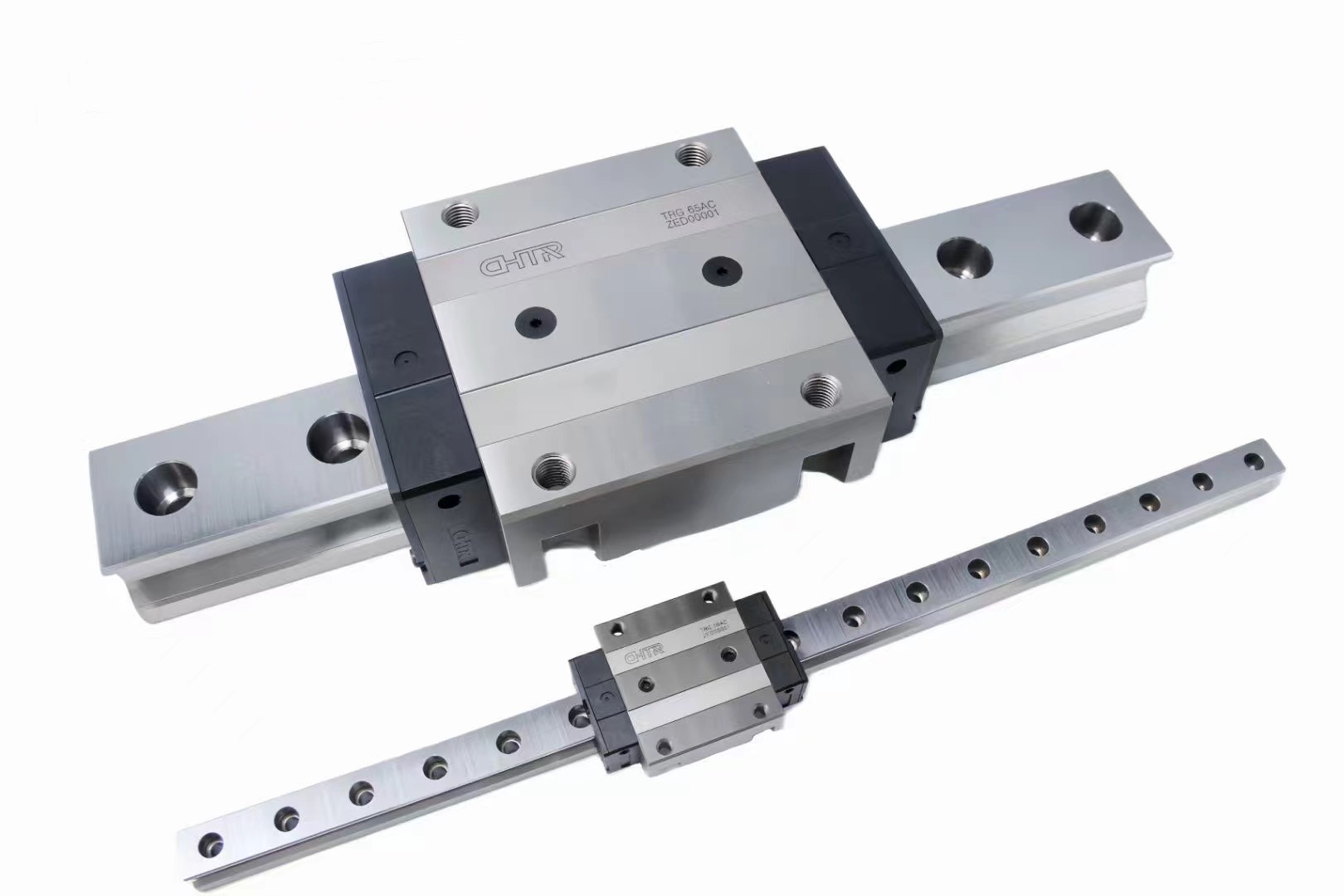

The High-Precision Motorised Linear Guide Slider is a linear motor guide motion system that integrates an electric drive and a high-precision linear guide. Motorized linear guide is widely used in automation equipment, precision machining, experimental instruments and robotics. This motorized linear guide system is driven by electric motor and combined with linear guide slider to achieve high-precision linear motion and positioning. Motorized linear guide greatly improves the working efficiency and processing accuracy.

Motorized linear guide is one of the core components of this system. Motorized linear guide drives the slider by electric motor to carry out precise linear motion along the guide. Compared with the traditional manual operation, motorised linear guide can not only control the displacement more quickly and accurately, but also automate the operation through the control system. Linear motor guide significantly reduces the human intervention and error. Linear motor guide usually use stepper motors or servo motors as the drive source, these linear motor guide can provide strong power and precise displacement control. Linear motor guide is suitable for a variety of high-precision task requirements.

The linear guide slider is another important part of the system. Motorized linear guide responsible for sliding smoothly on the guideway and carrying the load. The linear guide slider is usually made of high-strength materials with internal ball bearing systems or roller assemblies. Motorized linear guide significantly reduce friction and enable low-noise, smooth movement. The close fit of the linear motor guide to the guideway ensures that high precision linear motion is maintained at high speeds or under high loads, with no stalling or deflection. The compact design of the linear slider and linear motor guide can withstand multi-directional forces and adapt to complex industrial occasions.

The advantages of the High-Precision Motorised Linear Guide Slider System (High-Precision linear guide) lie in its automation and high precision features. Through the combination of electric drive and High-Precision linear guide, the High-Precision linear guide system can achieve high-speed, accurate displacement control, making High-Precision linear guide widely used in automated production lines, semiconductor manufacturing equipment and precision instruments. Especially in scenarios that require frequent repetitive positioning or long periods of continuous operation, these systems can significantly improve work efficiency, reduce errors and extend equipment life.

In addition, these High-Precision linear guide systems are scalable and flexible. By combining with other automation equipment or control systems, the motorised linear guide slide system can be easily integrated into complex production processes, further increasing the degree of automation of the production line. At the same time, the High-Precision linear guide system is easy to maintain, and the wear-resistant design of the slider and guideway ensures smooth operation over long periods of time, reducing maintenance costs.

In conclusion, the High-Precision Motorised Linear Guide Slider is a powerful, precise and efficient linear motion solution for a wide range of industrial applications requiring precise displacement and automation. Through the combination of motorised drive and high-precision guide slides, linear motor guide provides modern industry with great convenience and efficient production solutions.

Load capacity is determined by dynamic (C) and static (C₀) load ratings. For example: A 6205 deep groove ball bearing has a dynamic load rating of 14 kN, suitable for small motors. For heavy loads, choose tapered roller bearings (e.g., 32208 with C=90 kN). Recommendation: Share your equipment’s load analysis for optimal bearing selection.

Materials: Stainless steel (440C/316) or coatings (nickel plating, DLC). Seals: Double rubber seals (2RS) or PTFE seals. Example: Seawater pumps often use 316 stainless steel bearings with lifelong grease.

Speed limits depend on bearing type and lubrication: Standard 608ZZ ball bearings: ~18,000 rpm. Hybrid ceramic bearings (Si3N4 balls): 30–50% higher speeds. Solution: For high-speed applications, opt for oil lubrication or low-friction design.

Theoretical lifespan: Based on load calculations (see Q1). Real-world factors: Lubrication intervals (e.g., grease replenishment every 100km). Mounting surface flatness (≤0.01mm/m required). Tool: Free lifespan calculation software available.

Must-check: Slider hole spacing (e.g., 45mm×45mm). Rail width (15/20/25mm, etc.). Slider height (impacts machine space). Pro tip: Old slider model numbers are often engraved on the side.

Of course, we provide customized service, including add customers’ logo on the products, customized size of linear guide rail.

It according to the products, we usually can adjust the quantity according to customers’ request.

Invoices are automatically emailed to you when you complete your order. If you did not receive one contact us and provide your order number so we can find your order.

When your order ships you will receive an email with a tracking number which should have an estimated delivery date. Check your spam folder if you do not see it in your inbox. For more information on shipping, please reference our shipping policy.

You can either fill out the contact us form on our website, or head over to our sister website ngsbearing.com and request a quote over there for any product you see here on Bearings Direct. Please note that there will be minimum order quantities.