Precision linear slide is heavy load linear guide way designed by circular-arc groove and structure optimization are higher over 30% load capacity and rigidity than other similar ball type industrial linear slides. Precision linear slide features the same load in four directions (up/down/right/left) and self-aligning to absorb installation-error capability.

Linear Motion Slide Rails For High-Speed Machinery is a linear guide systems designed for high-speed machinery and equipment. The linear guide systems and industrial linear slides are widely used in industrial automation, precision machining. Precision linear slides are the core components of the linear guide systems, ensuring that machinery and equipment can achieve high-precision linear motion.

Linear Motion Slide Rails for high-speed machinery offer several key advantages. Industrial linear slides and linear guide systems provide high precision and accuracy, ensuring tight tolerances and exact positioning. Designed to handle high speeds, some industrial linear slides and linear guide systems can reach up to 10 meters per second. These industrial linear slides and rails feature low friction and wear-resistant materials, minimizing maintenance and downtime. Their robust construction and ability to handle high loads without deflection ensure stability and reliability in demanding industrial environments.

Linear guide systems consist of rails and industrial linear slides that are designed to reduce friction and improve smoothness of movement. This precision linear slides system distributes the load evenly across the guideway through the balls or rollers inside the carriage, ensuring precise positioning at high speeds. Highly rigid materials and precision manufacturing processes enable the linear guide system to maintain a high degree of stability and durability under high loads and long periods of operation.

Another advantage of precision linear slides is their flexibility and compatibility. These linear slide assemblies systems are usually designed to be modular and linear slide assemblies can be easily integrated into different types of machinery. In addition, the compact structure and efficient design of linear slide systems and linear slide assemblies allow for efficient industrial linear slides even in limited spaces, making linear guide systems suitable for modern, high-density production environments.

Linear Motion Slide Rails For High-Speed Machinery provides an efficient, precise and durable solution to meet the complex operational needs of high-speed machinery and equipment. These linear slide assemblies systems improve the overall performance of the equipment. Linear slide assemblies also reduce maintenance. Linear slide assemblies are widely used in automation equipment requiring high precision and speed, such as CNC machine tools, printing equipment.

Precision linear slides, achieved through advanced grinding technologies, offer several key advantages. These industrial linear slides systems provide high accuracy and precision, enabling micrometer-level positioning accuracy suitable for applications requiring tight tolerances. Linear motion slide rails are designed for smooth, low-friction movement, which enhances efficiency and reduces wear. Additionally, the extended lubrication life, due to grease pockets built into the recirculation path, reduces maintenance needs and extends the service life of the precision linear slides. These features make precision linear slides ideal for high-speed machinery in various industrial applications.

Load capacity is determined by dynamic (C) and static (C₀) load ratings. For example: A 6205 deep groove ball bearing has a dynamic load rating of 14 kN, suitable for small motors. For heavy loads, choose tapered roller bearings (e.g., 32208 with C=90 kN). Recommendation: Share your equipment’s load analysis for optimal bearing selection.

Materials: Stainless steel (440C/316) or coatings (nickel plating, DLC). Seals: Double rubber seals (2RS) or PTFE seals. Example: Seawater pumps often use 316 stainless steel bearings with lifelong grease.

Speed limits depend on bearing type and lubrication: Standard 608ZZ ball bearings: ~18,000 rpm. Hybrid ceramic bearings (Si3N4 balls): 30–50% higher speeds. Solution: For high-speed applications, opt for oil lubrication or low-friction design.

Theoretical lifespan: Based on load calculations (see Q1). Real-world factors: Lubrication intervals (e.g., grease replenishment every 100km). Mounting surface flatness (≤0.01mm/m required). Tool: Free lifespan calculation software available.

Must-check: Slider hole spacing (e.g., 45mm×45mm). Rail width (15/20/25mm, etc.). Slider height (impacts machine space). Pro tip: Old slider model numbers are often engraved on the side.

Of course, we provide customized service, including add customers’ logo on the products, customized size of linear guide rail.

It according to the products, we usually can adjust the quantity according to customers’ request.

Invoices are automatically emailed to you when you complete your order. If you did not receive one contact us and provide your order number so we can find your order.

When your order ships you will receive an email with a tracking number which should have an estimated delivery date. Check your spam folder if you do not see it in your inbox. For more information on shipping, please reference our shipping policy.

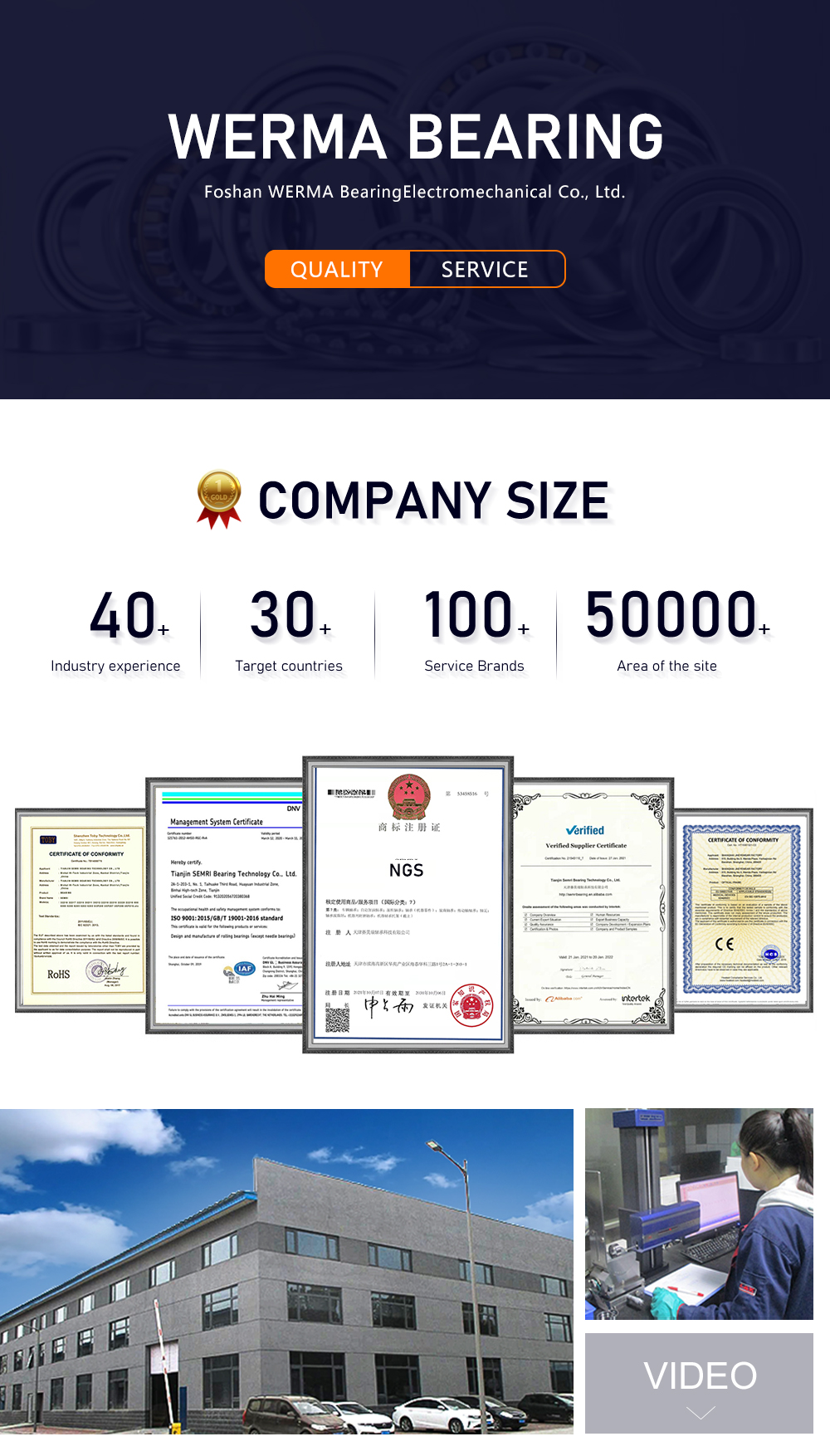

You can either fill out the contact us form on our website, or head over to our sister website ngsbearing.com and request a quote over there for any product you see here on Bearings Direct. Please note that there will be minimum order quantities.