- Home

- >

- Products

- >

- Linear Guideway

- >

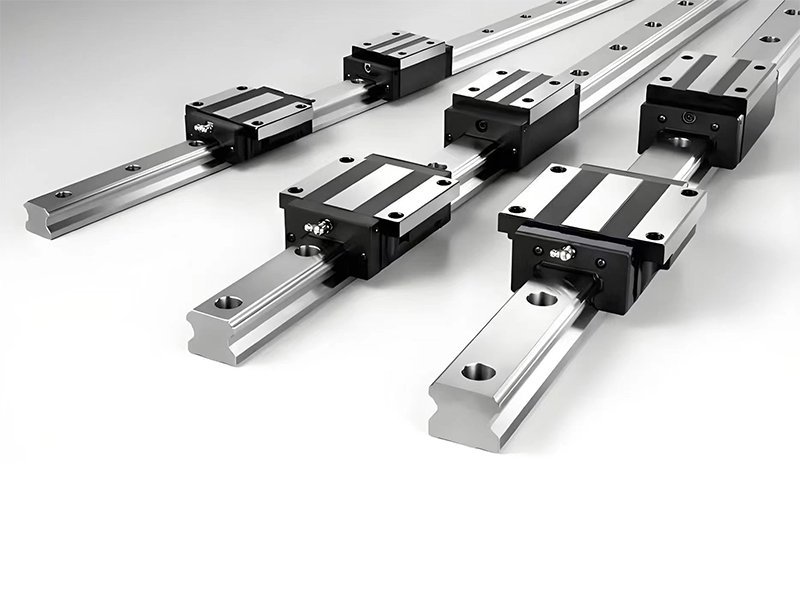

* High rigidity and high load capacity to linear guide bearing block * Complete product range for Linear Guideway Block * Linear guide shaft with High rigidity and high load capacity * Optimised design and Ultra-long life to linear guides and bearings

Email More

High-Precision Linear Guide Rail With Block Slider is a fixed beam cut to length, along which any number of items can move freely using linear movement, depending on the load needed and the configuration of the fixture. The vertical linear guide rails carriage which sits on the linear rail, contains the linear bearings which provide contact points between the two. High precision linear guides are typically used on doors, machine guarding and seating. Also, ball bearing linear guide is divided to high load capacity with standard block length and ultra high load capacity with longer block length.

Email More

High Precision linear motion slide through precision grinding processes to ensure accurate motion. Professional Linear Motion Slide can move smoothly without deflection and low noise while using. Linear Motion Slide can resist chemical corrosion and high temperatures. High Precision linear motion slide has long service life. Linear Guide Rail slide kit includes 2 pieces of 1500mm/59 long HGR20 rail and 4 Block Bearing. Linear Guide Rail with Pre-drilled holes on the Support Rail Mounts for ease of mounting. CNC linear guide rail is widely used in CNC milling machines, lathes and other equipment. Linear Guide Rail factory with 100% Brand new and high quality. Our Linear Guide Rail factory is known for high-quality products and reliable service.

Email More

Linear guide sliders are designed to provide a free motion in one direction and are the most common type of linear slide, offering a smooth precision motion along a single axis linear design. Most commonly used within the furniture industry as a ball-bearing drawer slide. Bearing linear guide is bearing elements for translation type motion (motion along a path). Unlike roller bearings, durable linear guides move on a shaft or static guide way, as opposed to on movable component slides. Depending on the type of guiding system, the sliding layer is applied to the rigid or movable component.

Email More

The steel linear guide is a design of rolling motion with a low friction coefficient, and the difference between dynamic and static friction is very small. Therefore, the stick-slip will not occur when sub micron feeding is making. To To the manual linear guide, due to the characteristic of low frictional resistance, the required driving force is much lower than in other systems, thus the power consumption is small. Moreover, the temperature rising effect is small even under high speed operation. Compared with the high-skill required scrapping process of conventional slide guide, the star linear guide can offer high precision even if the mounting surface is machined by milling or grinding. Moreover the interchangeability of Stainless Steel Linear Guide gives a convenience for installation and future maintenance.

Email More

The heavy load linear guide assembly consists of guide, slide, steel ball, reverses, retainer, seal end and baffle etc. Micro linear guide is used in applications where space is extremely tight and precision is required. Curved linear guideways are ideal for scenarios where movement along a curve is required. Belt drive linear guide rail, on the other hand, are a type of linear motion device driven by a belt. Belt drive linear guide rail excels in applications that require long, fast and smooth movements.

Email More