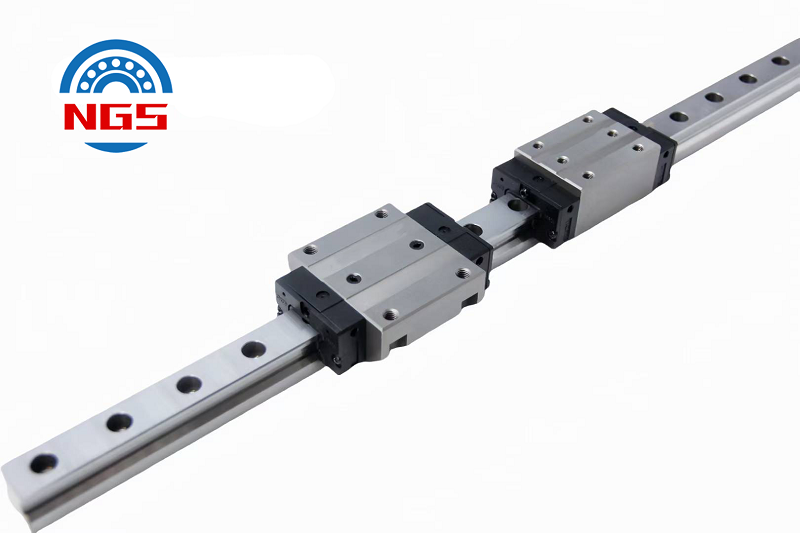

High-Precision Linear Guide Rail With Block Slider is a fixed beam cut to length, along which any number of items can move freely using linear movement, depending on the load needed and the configuration of the fixture. The vertical linear guide rails carriage which sits on the linear rail, contains the linear bearings which provide contact points between the two. High precision linear guides are typically used on doors, machine guarding and seating. Also, ball bearing linear guide is divided to high load capacity with standard block length and ultra high load capacity with longer block length.

Email More

Linear guide sliders are designed to provide a free motion in one direction and are the most common type of linear slide, offering a smooth precision motion along a single axis linear design. Most commonly used within the furniture industry as a ball-bearing drawer slide. Bearing linear guide is bearing elements for translation type motion (motion along a path). Unlike roller bearings, durable linear guides move on a shaft or static guide way, as opposed to on movable component slides. Depending on the type of guiding system, the sliding layer is applied to the rigid or movable component.

Email More

The primary advantage of a modern CNC linear guide with a roller bearing linear guide is its exceptional rigidity. This bearing linear rail and bearing linear slide combination provides a very high load capacity for a linear bearing slide rails system.

Email More

Our roller bearing guide rails systems deliver a revolutionary performance upgrade. The line contact of our roller bearing guide rails or roller bearing rail provides a much larger contact area than ball points. Our optimized linear roller bearing track or roller bearing rail recirculation design and highly efficient sealing system enable smooth, high-speed operation. Roller bearing linear guide or roller bearing linear guide rails are suitable for Machining Centers, CNC Mills.

Email More