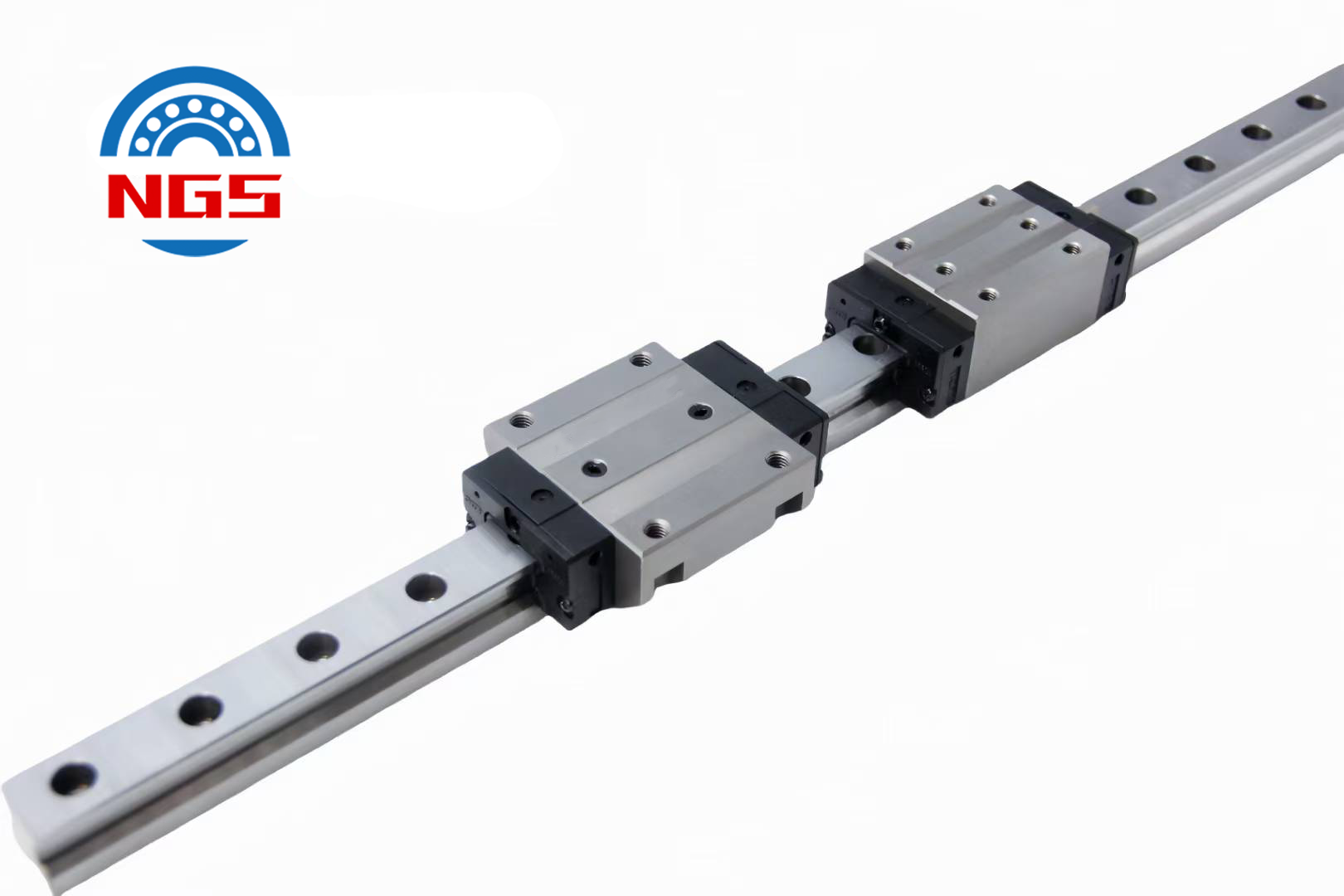

In an era demanding higher precision, speed, and longevity from machinery, selecting the right roller bearing guide rails is critical. Our roller bearing guide rails systems deliver a revolutionary performance upgrade by replacing the point contact of traditional ball guides with optimized line contact.

Superior Rigidity & Load Capacity

Core Advantage: The line contact of our roller bearing guide rails provides a much larger contact area than ball points. This results in a load capacity 2-3 times higher and rigidity up to 200% greater than comparable ball guide sizes.

Your Benefit: Your equipment can handle heavier loads, resist significant shock forces, and maintain extreme stability with minimal deformation.

Unmatched Running Accuracy & Stability of roller bearing linear guide

Core Advantage: The larger contact area of roller bearing linear guide ensures uniform stress distribution and minimal elastic deformation under load. This advantage of roller bearing linear guide guarantees consistent, high-precision motion and effectively suppresses vibration and stick-slip.

Your Benefit: Achieve stable and precise trajectories for your machining centers and measuring

Extended Service Life & Enhanced Reliability

Core Advantage: Dramatically reduced contact stress leads to significantly slower wear. Under identical operating conditions, our roller bearing linear guide rails achieve a calculated (L10) service life far exceeding that of ball guides.

Your Benefit: Drastically extend machine overhaul intervals, reduce unplanned downtime, and lower the Total Cost of Ownership (TCO) through fewer component replacements of roller bearing linear guide rails.

Optimized for High Speeds & Acceleration of roller bearing rail

Core Advantage: Our optimized linear roller bearing track recirculation design and highly efficient sealing system enable smooth, high-speed operation while maintaining low noise and minimal temperature rise.

Your Benefit: linear roller bearing track can meet the demanding requirements for high cycle times and efficiency in automation and robotics applications.

Our roller bearing rail are the ideal solution for industries where performance under stress is non-negotiable:

High-Precision Machine Tools: VMCs/HMCs, Turning-Milling Centers, Precision Grinders.

Heavy-Duty & Large-Scale Equipment: Gantry Mills, Laser Cutters, Stamping Presses, Injection Molding Machines.

Semiconductor & Electronics Manufacturing: IC Encapsulation Machines, PCB Drillers, Wafer Handling Robots.

Automation & Industrial Robotics: Large Cartesian Robots, Material Handling Robots, Automated Assembly Lines.

New Energy & Medical Equipment: Battery Stacking Machines, PV Panel Processing Equipment, Medical Imaging Scanner Beds.

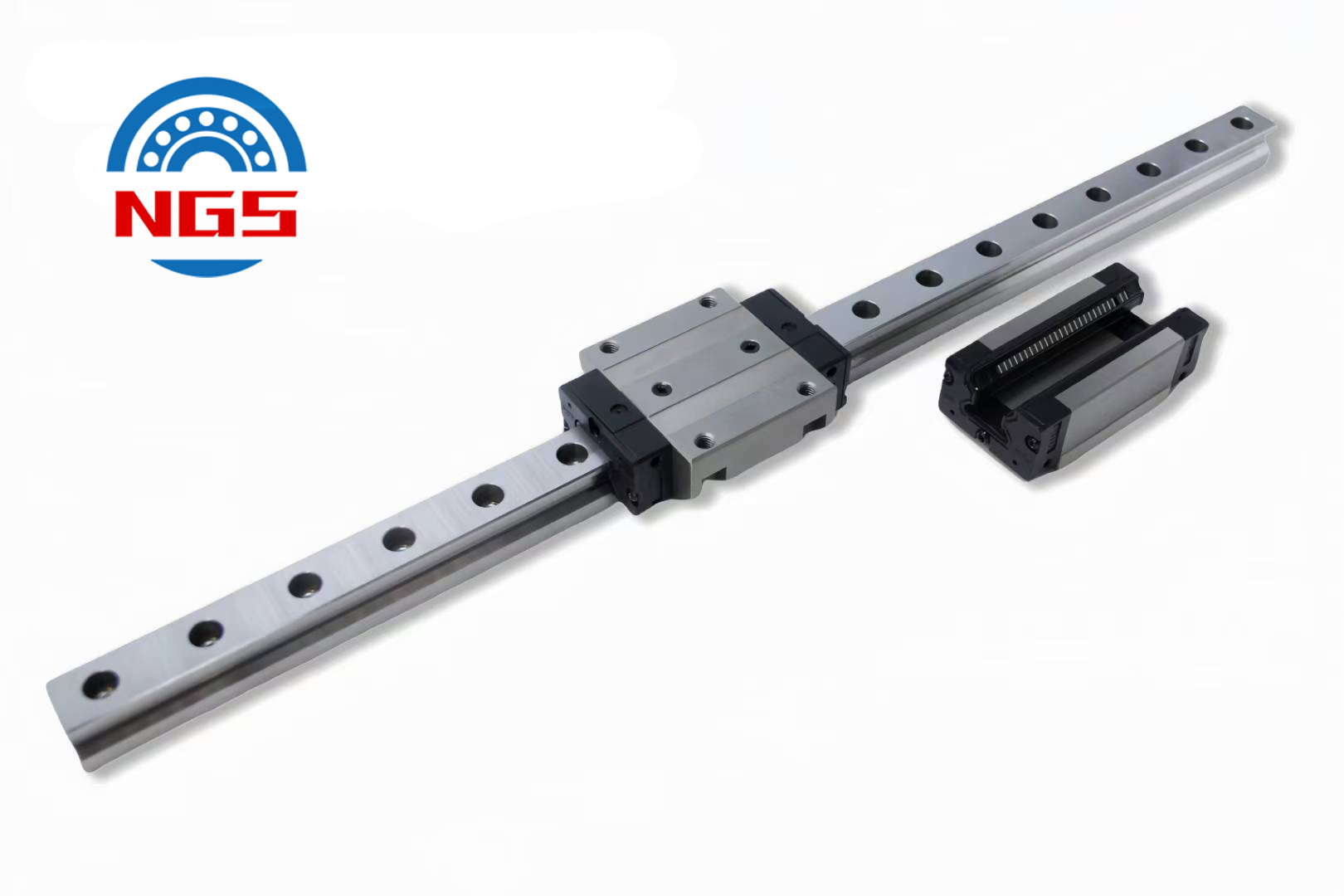

Our Core linear roller bearing track or roller bearing rail Series:

| Series Name | HIWIN-Compatible Series | Rail Width (mm) | Key Features | Ideal For |

|---|---|---|---|---|

| RGW Series | RG Series | 15, 20, 25, 30, 35, 45 | Standard High Rigidity. 4-way equal load capacity for all-around high performance. | Machining Centers, CNC Mills, General Automation |

| RGH Series | RG Series | 15, 20, 25, 30, 35, 45, 55 | Heavy-Load Type. Larger rollers and reinforced block structure for maximum capacity and rigidity. |

We understand that fast delivery is critical to your project's success.

Standard Model Stock of roller bearing rail:

Popular models of roller bearing rail (e.g., RGW/RGH 20, 25, 30, 35, 45) are held in secure, ready-to-ship inventory.

Our Promise: Orders for in-stock roller bearing linear guide rails are processed and dispatched within ≤ 7 business days.

Global Logistics:

We partner with global leaders like DHL and FEDEX to provide you with fast and reliable door-to-door shipping worldwide.

When you choose our roller bearing linear guide rails, you gain more than a component—you gain a reliable technical partner.

Free Application Sizing:

Our application engineering team provides free load, life, and accuracy calculations.

Installation Guidance & Troubleshooting:

We provide high-definition installation tutorial videos of linear roller bearing track and step-by-step manuals.

Contact our technical experts today for a free linear roller bearing track review and a customized quote.

Load capacity is determined by dynamic (C) and static (C₀) load ratings. For example: A 6205 deep groove ball bearing has a dynamic load rating of 14 kN, suitable for small motors. For heavy loads, choose tapered roller bearings (e.g., 32208 with C=90 kN). Recommendation: Share your equipment’s load analysis for optimal bearing selection.

Materials: Stainless steel (440C/316) or coatings (nickel plating, DLC). Seals: Double rubber seals (2RS) or PTFE seals. Example: Seawater pumps often use 316 stainless steel bearings with lifelong grease.

Speed limits depend on bearing type and lubrication: Standard 608ZZ ball bearings: ~18,000 rpm. Hybrid ceramic bearings (Si3N4 balls): 30–50% higher speeds. Solution: For high-speed applications, opt for oil lubrication or low-friction design.

Theoretical lifespan: Based on load calculations (see Q1). Real-world factors: Lubrication intervals (e.g., grease replenishment every 100km). Mounting surface flatness (≤0.01mm/m required). Tool: Free lifespan calculation software available.

Must-check: Slider hole spacing (e.g., 45mm×45mm). Rail width (15/20/25mm, etc.). Slider height (impacts machine space). Pro tip: Old slider model numbers are often engraved on the side.

Of course, we provide customized service, including add customers’ logo on the products, customized size of linear guide rail.

It according to the products, we usually can adjust the quantity according to customers’ request.

Invoices are automatically emailed to you when you complete your order. If you did not receive one contact us and provide your order number so we can find your order.

When your order ships you will receive an email with a tracking number which should have an estimated delivery date. Check your spam folder if you do not see it in your inbox. For more information on shipping, please reference our shipping policy.

You can either fill out the contact us form on our website, or head over to our sister website ngsbearing.com and request a quote over there for any product you see here on Bearings Direct. Please note that there will be minimum order quantities.