What are Linear Guide Rails and Sliders?

Linear guide rails (Linear Guideways) and sliders (Blocks) are core components in modern precision machinery that enable linear motion. Linear guide rails are widely used in high-precision fields such as CNC machine tools, automated equipment, 3D printers, and medical devices, cnc linear guide rails form a high-precision, low-friction linear motion system. By replacing traditional sliding friction methods, cnc linear guide rails significantly improve equipment positioning accuracy and service life.

Structure and Working Principle of Linear Guide Rails ?

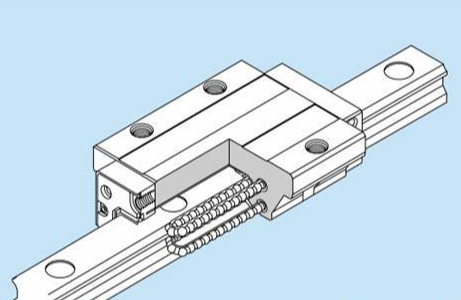

Basic Structure

Rail: Typically made of high-strength alloy steel, precision-ground and hardened for exceptional straightness and hardness.

Sliders: Linear guide sliders contains internally mounted balls or rollers that enable smooth motion through cyclic rolling, reducing friction.

End Caps and Seals: Prevent contamination from dust or debris, extending service life.

Working Principle

cnc linear guide rails utilize rolling friction instead of traditional sliding friction. Balls or rollers inside the sliders cycle along the rail track, achieving high-precision, high-rigidity, low-friction linear motion.

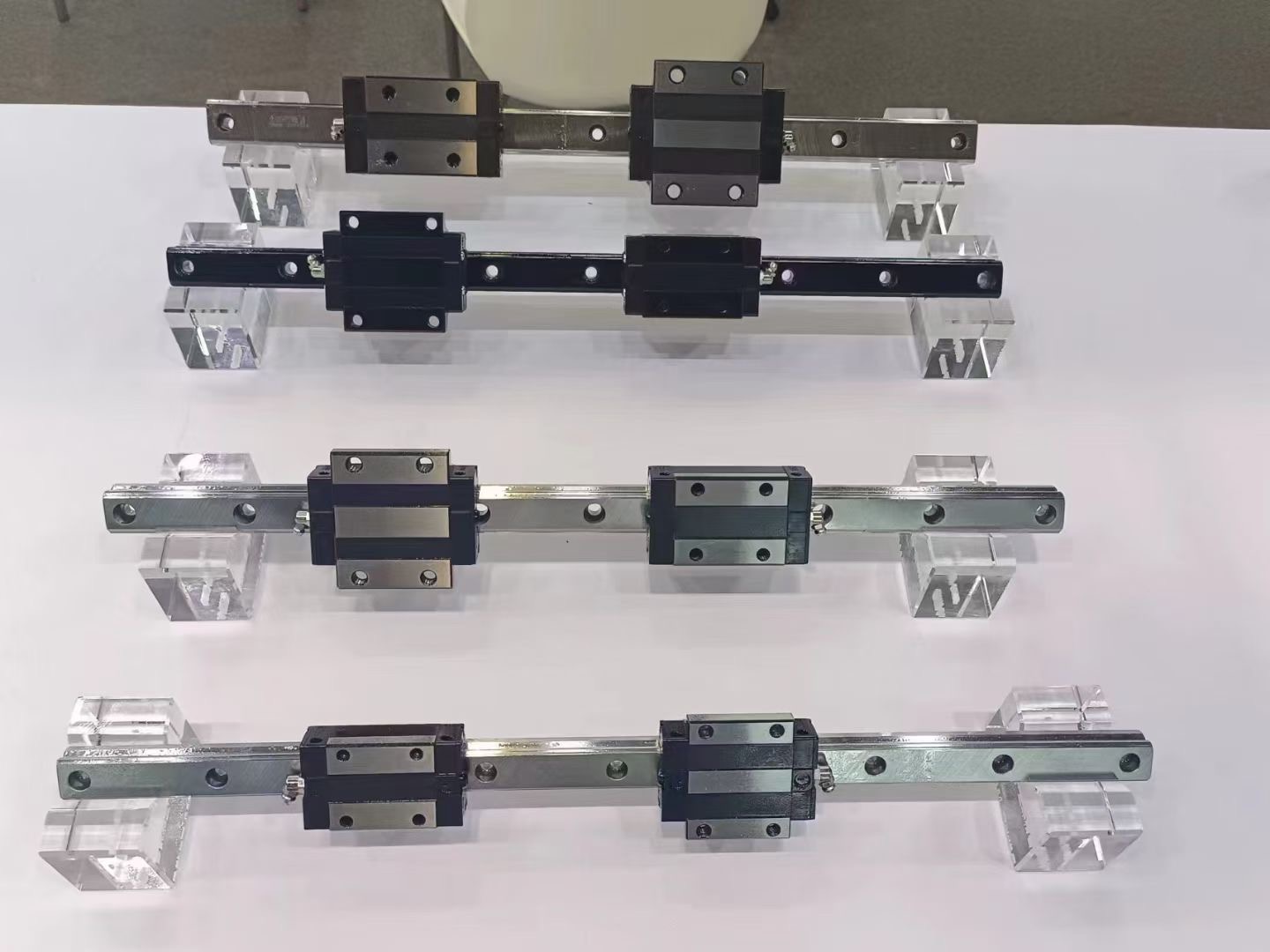

Main Types of Linear Guides and sliders

| Type | Characteristics | Applications |

| Ball Linear Guide and sliders | Low friction, high speed, light load | 3D printers, small automation equipment |

| Roller Linear Guide and sliders | High rigidity, heavy load, high precision | CNC machine tools, heavy machinery |

| Miniature Linear Guide and sliders | low noise Medical devices | optical instruments |

| Magnetic Levitation Guide and sliders | Contactless, ultra-high precision | Semiconductor equipment, precision measurement |

How to Select the Right Linear Guide and sliders ?

As a cnc linear guide rails manufacturer, we'd like to discuss how to choose the right linear guide and sliders. For example, HGR20 linear rail and sliders, we need to check determine load requirements, precision level, environmental factors,match drive method. As a professional linear guide rails manufacturer-NGS can provide different types HGR20 linear rail. Load calculation must comprehensively consider radial, axial, and moment loads, typically with a safety factor of 1.2-2. Life calculation uses the formula L=(C/P)³×50km. In practical applications, HGR20 linear rail systems of linear guide rails manufacturer-NGS demonstrate outstanding performance. Our HGR20 linear rail systems are high reputation. What's more, the size of HGR20 linear rail is suitable for many machine, so HGR20 linear rail can be used in many areas. We also design many different types of looks of HGR20 linear rail sliders to meet customer's needs.

How maintain the linear rails and sliders ?

To ensure long-term stable operation of cnc linear guide rails and sliders systems, standardized maintenance procedures must be followed. Daily maintenance should pay attention to lubrication intervals, with grease lubrication typically replenished every 6-12 months and oil lubrication requiring continuous supply. Cleaning of cnc linear guide rails and sliders should use lint-free cloths and specialized cleaners, strictly avoiding corrosive solvents like acetone. When abnormalities such as unusual noise or motion sticking occur, causes should be promptly identified and appropriate measures taken.

Future Development Trends

Looking ahead, as a cnc linear guide rails manufacturer, we believe technology of linear guide and sliders will develop in three main directions: magnetic levitation guide and sliders technology will achieve contactless motion and nanometer-level accuracy; self-sensing intelligent guides will feature real-time health monitoring and adaptive compensation; miniaturization will drive the application of linear guides in emerging fields like medical robotics. These technological innovations will further consolidate the core position of linear guides and sliders in modern industry.

As key components of modern precision machinery, most of linear guide rails manufacturer think the technological level of linear guide and sliders systems directly impacts the development of equipment manufacturing. With the integration and innovation of new materials, intelligence, and green manufacturing technologies, linear guides are continuously advancing toward higher accuracy, longer life, and greater intelligence. Against the backdrop of China's manufacturing transformation and upgrading, domestic linear guides are expected to achieve greater breakthroughs in high-end markets, making significant contributions to global industrial progress.