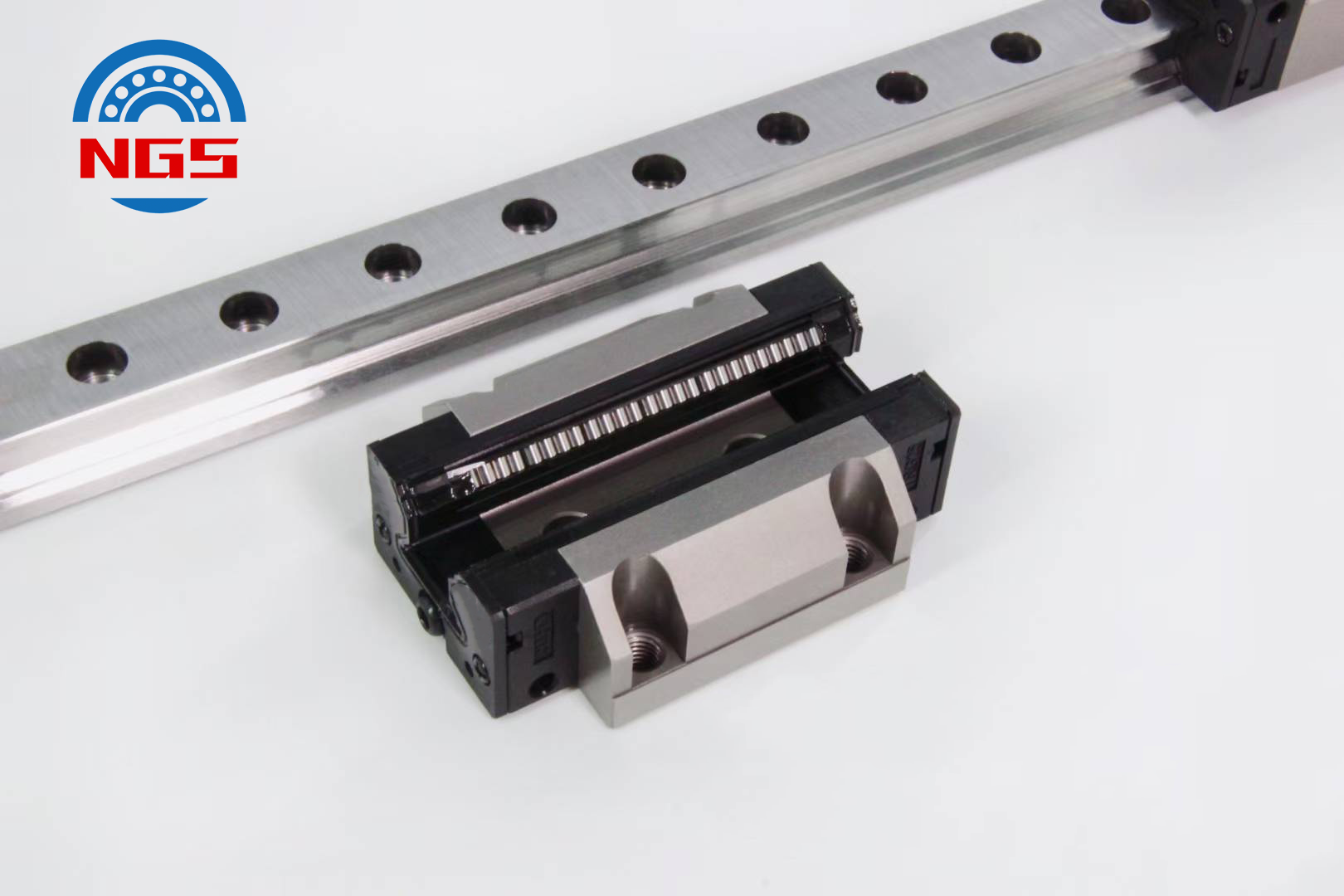

Heavy duty roller guide rails can be thought of as the "powerhouses" or "heavy-haul trucks" of the linear motion world. Heavy duty roller guide rails inherit all the fundamental advantages of standard roller guides—high rigidity and high load capacity—and heavy duty roller guide rails are specifically engineered with robust enhancements to withstand the most extreme and demanding applications.

What are Heavy-Duty Roller Linear Guide ?

Heavy-duty roller linear guides are linear motion systems specifically designed to handle extremely high loads, significant shock loads, and powerful moments. Heavy duty roller guide rails primary function is to provide a stable, precise, and reliable foundation for movement in heavy machinery, under conditions where standard guides would fail.

Key Design Features

Heavy-duty guides are significantly enhanced in several critical areas:

Dimensions and Structural Reinforcement

Larger Sizes: heavy duty roller guide rails and roller rail track are manufactured in much larger sizes than standard guides, e.g., sizes 65, 85, 120, and above (compared to common sizes like 45).

Wider Rails and Blocks: Heavy duty roller guide and linear roller bearing track provides a greater support area and linear roller bearing track vastly improved resistance to overturning moments.

Thicker Raceway Walls: The material around the rolling element pathways is substantially thicker to withstand extreme contact stresses without deformation.

Enhanced Roller System

Increased Number of Rollers: The blocks incorporate a greater quantity of larger-diameter rollers, distributing the load over more contact points to dramatically increase capacity.

Optimized Roller Profile: Often feature crowned rollers (slightly barrel-shaped) to compensate for minor rail deflection under immense load. This ensures even load distribution across all rollers, preventing stress concentration and extending service life.

High-Strength Retainer

Utilizes retainers of linear roller bearing track made from high-strength steel or advanced engineering plastics to maintain precise roller spacing under high speed and load, preventing roller-to-roller contact.

Heavy-Duty Sealing and Lubrication

Multi-Stage Sealing: Equipped with multi-lip, labyrinth seals to provide maximum protection against contaminants like metal chips, abrasive dust, and coolant in harsh environments.

Advanced Lubrication: Typically feature standard grease nipples and are often compatible with centralized automatic lubrication systems. This ensures continuous lubrication of the raceways and rollers over long travel distances under heavy load, preventing wear and seizure.

Reinforced Mounting Structure

Feature more and larger mounting screw holes, allowing the block to be securely fastened to the machine base to prevent loosening under shock loads.

Advantages of NGS heavy duty roller guide rails

Exceptional Static and Dynamic Load Capacity: Heavy-duty linear motion rolling guides or roller rail track capable of supporting loads ranging from tens to hundreds of tons, forming the backbone of heavy equipment.

Superior Rigidity: Minimal elastic deformation under sudden, immense forces of Heavy-duty linear motion rolling guides or roller rail track (e.g., heavy cutting, stamping) ensures machining accuracy and stability.

Outstanding Moment Resistance: The large footprint of Heavy-duty linear motion rolling guides or roller rail track provides excellent resistance to overturning moments caused by off-center loads, ensuring smooth and safe operation.

Extended Service Life: Robust design of Heavy-duty linear motion rolling guides or roller rail track and proper lubrication of Heavy-duty linear motion rolling guides or roller rail track lead to a dramatically longer fatigue life than standard guides, even in severe conditions, reducing maintenance costs and downtime.

High Reliability: The rugged construction and superior sealing of heavy duty roller guide or roller rail track ensure stable operation in adverse industrial environments characterized by dust, moisture, and vibration.

Typical application

Extra-Large CNC Machine Tools:

Gantry Machining Centers: Especially large 5-axis mills for aerospace components, mold/die making, and wind power equipment.

Floor-Type Boring and Milling Machines: For machining large holes and surfaces on massive workpieces.

Heavy-Duty Lathes and Grinders.

Heavy Industrial Machinery:

Presses and Punching Machines: Ultra-large stamping lines in automotive manufacturing.

Forging Equipment: Withstands significant impact loads.

Steel Rolling Mills: Operates in high-temperature, high-load environments.

Large-Scale Material Handling Systems:

Port Container Cranes: Movement mechanisms for gantries and trolleys.

Automated Storage and Retrieval Systems (AS/RS): For the stacker cranes.

Heavy-Duty AGVs/RGVs (Automated Guided Vehicles/Rail Guided Vehicles).

Renewable Energy and Heavy Equipment:

Wind Turbines: Used in pitch and yaw control systems.

Heavy Engineering Machinery: Such as the thrust system in Tunnel Boring Machines (TBMs).

Load capacity is determined by dynamic (C) and static (C₀) load ratings. For example: A 6205 deep groove ball bearing has a dynamic load rating of 14 kN, suitable for small motors. For heavy loads, choose tapered roller bearings (e.g., 32208 with C=90 kN). Recommendation: Share your equipment’s load analysis for optimal bearing selection.

Materials: Stainless steel (440C/316) or coatings (nickel plating, DLC). Seals: Double rubber seals (2RS) or PTFE seals. Example: Seawater pumps often use 316 stainless steel bearings with lifelong grease.

Speed limits depend on bearing type and lubrication: Standard 608ZZ ball bearings: ~18,000 rpm. Hybrid ceramic bearings (Si3N4 balls): 30–50% higher speeds. Solution: For high-speed applications, opt for oil lubrication or low-friction design.

Theoretical lifespan: Based on load calculations (see Q1). Real-world factors: Lubrication intervals (e.g., grease replenishment every 100km). Mounting surface flatness (≤0.01mm/m required). Tool: Free lifespan calculation software available.

Must-check: Slider hole spacing (e.g., 45mm×45mm). Rail width (15/20/25mm, etc.). Slider height (impacts machine space). Pro tip: Old slider model numbers are often engraved on the side.

Of course, we provide customized service, including add customers’ logo on the products, customized size of linear guide rail.

It according to the products, we usually can adjust the quantity according to customers’ request.

Invoices are automatically emailed to you when you complete your order. If you did not receive one contact us and provide your order number so we can find your order.

When your order ships you will receive an email with a tracking number which should have an estimated delivery date. Check your spam folder if you do not see it in your inbox. For more information on shipping, please reference our shipping policy.

You can either fill out the contact us form on our website, or head over to our sister website ngsbearing.com and request a quote over there for any product you see here on Bearings Direct. Please note that there will be minimum order quantities.