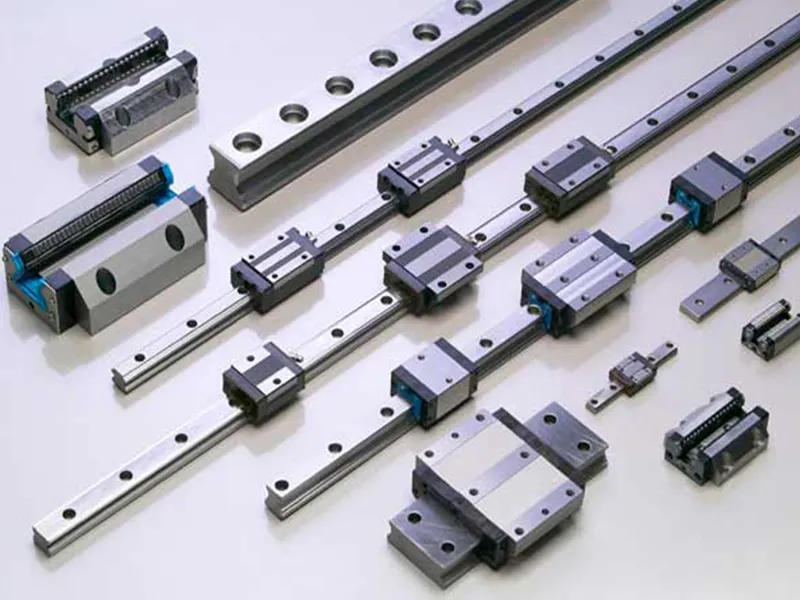

In the precise world of industrial automation and machinery, the linear guide and slider is the unsung hero of motion. linear guide and slider ensures accuracy, bears loads, and dictates the smoothness of operation. While standard catalog linear guide and slider serve a vast array of applications, high-precision linear guide represent a compromise. high-precision linear guide are designed for the "average" need.

But what happens when your application is anything but average? When it operates in a corrosive environment, demands unparalleled precision, or must fit into an impossibly compact space? This is where the compromise of a standard part becomes a liability.

Custom-designed linear guide and slider are the strategic answer. Custom-designed linear guide and slider are not a luxury but a critical engineering solution for OEMs and manufacturers who aim to push the boundaries of performance, reliability, and innovation. This in-depth guide explores why customizing your high-precision linear guide or cnc guide rails components is the key to unlocking your machine's full potential.

Compelling Reasons to Choose Custom linear guide and slider

Choosing a custom solution is a deliberate decision to solve specific problems that standard linear guide and slider or high-precision linear guide cannot. The drivers for customization typically fall into four key areas:

1. Conquering Extreme and Specialized Environments

Corrosion and Chemicals: Standard steel linear guide and slider or high-precision linear guide are vulnerable in food processing, chemical plants, or marine applications. Custom linear guide and slider can be manufactured from stainless steel or even high-performance engineering polymers.

Extreme Temperatures:Custom solutions of high-precision linear guide or cnc guide rails employ high-temperature stable polymers, special heat treatments, and wide-temperature greases of high-precision linear guide or cnc guide rails to ensure consistent performance.

Cleanroom and Vacuum Conditions: Custom cnc guide rails can be designed with special seals, low-vapor-pressure lubricants, or dry-running self-lubricating materials to meet ISO Class cleanroom or high-vacuum (up to 10⁻⁶ Pa) requirements.

2. Meeting Exceptional Performance and Dimensional Demands

Superior Accuracy and Rigidity: High-end machine tools and metrology equipment often require tolerances beyond standard offerings of cnc guide rails. Customization allows for selective matching of components, optimized preload, and specialized grinding techniques to achieve sub-micron level repeatability and extreme stiffness.

Non-Standard linear rail sizes and Shapes: When your design has spatial constraints or requires a unique linear rail sizes, custom linear rail sizes are the only option. We can produce extra-long rails (via splicing), compact sliders, or custom mounting hole patterns to integrate seamlessly into your assembly.

Key Industries That Rely on Custom Linear Guides

1. Semiconductor and Electronics Manufacturing

Applications: Wafer steppers, die bonders, pick-and-place robots, automated test equipment.

Custom Needs: Ultra-high cleanliness (low particulate generation), vacuum compatibility, incredible acceleration rates, and nanometer-level precision.

2. Medical and Life Sciences

Applications: MRI/CT scanners, surgical robotics, automated laboratory analyzers, patient positioning systems.

Custom Needs: Whisper-quiet operation, biocompatible materials and exceptionally smooth, stiction-free motion.

3. Food and Beverage Processing

Applications: Filling machines, labeling systems, packaging robots, conveyor systems.

Custom Needs: Full stainless-steel construction, IP69K-rated sealing for high-pressure washdowns, and use of FDA-compliant, non-toxic lubricants.

Our Spectrum of Customization Services

1. Geometric and Structural Customization

Length and Stroke: Unlimited travel lengths of cnc guide rails or linear rail sizes through proprietary rail-splicing technology.

Slider Geometry and Mounting: Custom footprints, non-standard hole patterns, and unique thread sizes to match your machine's base structure perfectly.

Rail Profile: Design of non-standard cnc guide rails or linear rail sizes cross-sections (e.g., square, rectangular) to meet specific structural needs.

2. Material Science and Finishing Customization

Core Materials: Choice of bearing steel, various stainless steels, aluminum alloys , and engineering plastics. or other types of linear rails.

Rolling Elements: Option for ceramic balls for higher speed, reduced thermal expansion, and non-magnetic properties.or other types of linear rails.

Surface Treatments and Coatings: Application of hard chrome plating, electroless nickel, black oxide, or specialized polymer coatings (e.g., Teflon) for enhanced corrosion resistance, reduced friction, or aesthetic purposes.or other types of linear rails.

3. Precision, Preload, and Performance Tuning

Accuracy Grades: Manufacturing to grades superior to standard catalog options (e.g., Precision, Ultra-Precision).or other types of linear rails, cnc guide rails and linear rail sizes.

Preload Adjustment: Precise internal preloading of the carriage to eliminate play and maximize system rigidity for your specific load conditions.or other types of linear rails, cnc guide rails and linear rail sizes.

Raceway Engineering: Optimization of the ball groove geometry and contact angle to support higher moment loads or complex load combinations. or other types of linear rails, cnc guide rails and linear rail sizes.

4. Lubrication and Sealing System Customization

Lubrication Solutions: Provision of food-grade grease, wide-temperature-range lubricants, solid lubricants (graphite, MoS2), or pre-drilled oil holes for centralized automatic lubrication systems.or other types of linear rails, cnc guide rails and linear rail sizes.

Sealing Technologies: Design of multi-lipped contact seals, labyrinth seals, or scrapers to protect against heavy dust, chips, coolants, or direct water ingress.or other types of linear rails, cnc guide rails and linear rail sizes.

The Tangible Benefits: The ROI of Customization

1. Optimized Machine Performance

A high-precision linear guide or cnc guide rails that is perfectly matched to its application will operate at peak efficiency in accuracy, speed, and smoothness. This directly enhances the performance and capability.or other types of linear rails, cnc guide rails and linear rail sizes.

2. Enhanced Reliability and Risk Mitigation

A purpose-built component, tested for its specific use case, is inherently more reliable. This drastically reduces the risk of in-field failures, costly warranty claims, and damage to your brand's reputation for quality.or other types of linear rails, cnc guide rails and linear rail sizes.

3. Streamlined Assembly and Reduced Manufacturing Cost

The "drop-in" fit of a custom-designed module eliminates hours of manual alignment, shimming, and adjustment during final assembly. This streamlines your production line, reduces labor costs, and minimizes the potential for human error. or other types of linear rails, cnc guide rails and linear rail sizes.

4. Unlocking Design Innovation

Customization frees your R&D team from the constraints of standard component sizes and performance. It enables the creation of more compact, powerful, and feature-rich machines that can define a new market category. or other types of linear rails, cnc guide rails and linear rail sizes.

Partner in Precision - Your Custom Journey Starts Here

In a competitive global landscape, the smallest component can make the biggest difference. A custom-designed linear guide is not just a part; it's a engineered solution that can become your competitive advantage.

We are more than a manufacturer; we are your engineering partner. With decades of experience and state-of-the-art production facilities, we are equipped to translate your most challenging requirements into a reliable, high-performance linear motion solution, or other types of linear rails, cnc guide rails and linear rail sizes.