As linear rail suppliers, NGS want to tell the truth that the high humidity during the rainy season can cause linear guides to rust, lose lubrication efficiency, and even reduce equipment precision and lifespan. For CNC machines, automation equipment, and industrial robots that rely on high-precision motion systems, proper maintenance is critical. This guide (from linear rail suppliers-NGS) covers essential anti-humidity, anti-rust, and lubrication strategies to prevent failures and extend the service life of your linear guides.

How the Rainy Season Affects Linear Guides ?

Most of linear rail suppliers and customers know that it will be affect in the follwing areas:

Rust & Corrosion – Moisture accelerates metal oxidation, leading to rust on rails and blocks.

Lubrication Failure – Humidity can contaminate grease, causing it to emulsify and lose effectiveness.

Dirt Accumulation – Damp conditions attract dust and debris, increasing wear.

Reduced Precision – Rust and poor lubrication increase friction, affecting positioning accuracy.

How to solve these problem ?

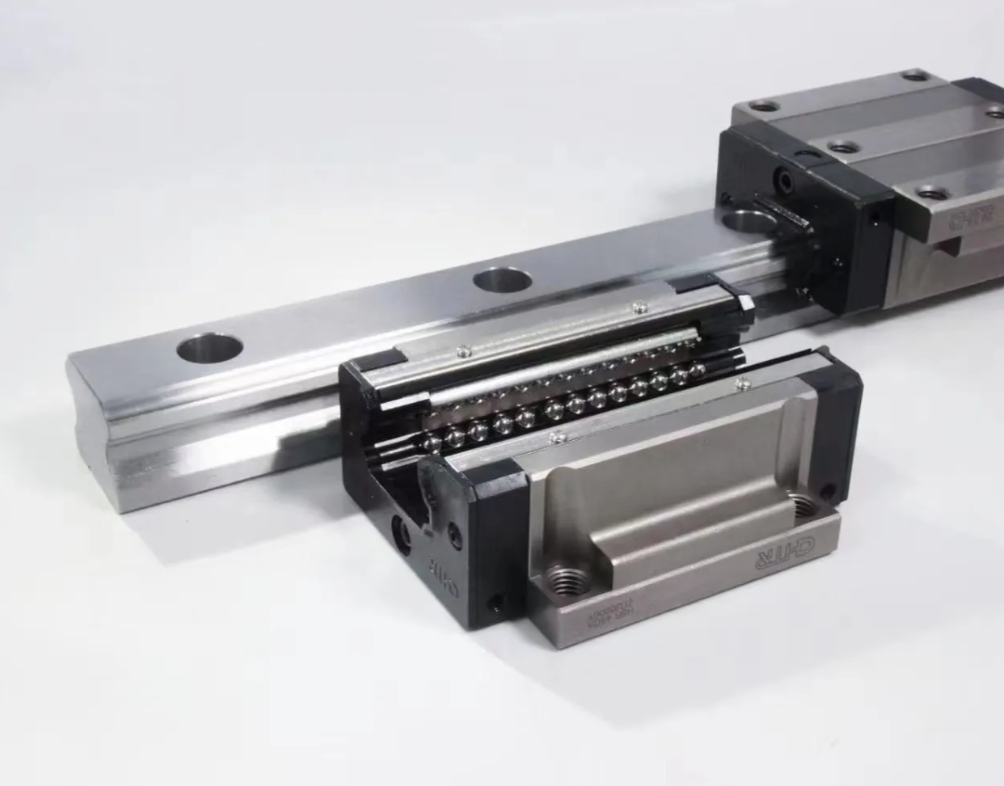

Stainless Steel Linear Guides & Blocks

Stainless steel linear guides or stainless steel linear rail and blocks are made from high-grade austenitic (304/316) or martensitic (440C) stainless steel, offering excellent corrosion resistance without additional coatings.

Superior Corrosion Resistance – stainless steel linear guides and stainless steel linear rail are ideal for humid, acidic, or saline environments (food processing, marine, medical applications).

Hygienic & Easy to Clean – Non-porous surface prevents bacterial growth, stainless steel linear guides and stainless steel linear rail are suitable for cleanrooms and pharmaceutical use.

No Plating Required – stainless steel linear guides and stainless steel linear rail maintain performance even if scratched (unlike coated guides).

High Strength – Martensitic grades (e.g., 440C) of stainless steel linear guides and stainless steel linear rail provide hardness comparable to hardened steel.

Hard Chrome Plated Linear Guides & Blocks

Standard carbon steel guides/blocks electroplated with a hard chromium layer (5–20μm) for enhanced wear and corrosion resistance.

Enhanced Durability – Chrome layer increases surface hardness (up to 70 HRC), reducing abrasive wear.

Moderate Corrosion Resistance – Protects against humidity, water splashes, and mild chemicals.

Cost-Effective Alternative – Cheaper than stainless steel while offering better rust protection than uncoated steel.

Smooth Running Surface – Low friction coefficient improves motion precision.

Hard Chrome Plated Linear Guides & Blocks

Standard carbon steel guides/blocks electroplated with a hard chromium layer (5–20μm) for enhanced wear and corrosion resistance.

Enhanced Durability – Chrome layer increases surface hardness (up to 70 HRC), reducing abrasive wear.

Moderate Corrosion Resistance – Protects against humidity, water splashes, and mild chemicals.

Cost-Effective Alternative – Cheaper than stainless steel while offering better rust protection than uncoated steel.

Smooth Running Surface – Low friction coefficient improves motion precision.

Essential Maintenance Tips

As linear rail suppliers, NGS want to tell:

1.Moisture Protection

Apply Anti-Rust Oil or Coating – Use products like WD-40 or specialized anti-corrosion sprays to create a protective film.

Control Humidity – Install dehumidifiers or air conditioners to maintain 40%-60% humidity.

Use Protective Covers – Install bellows or telescopic covers to shield open rails from moisture.

2.Optimize Lubrication

Choose Water-Resistant Grease – Use lithium-based or synthetic grease designed for humid conditions.

Increase Lubrication Frequency – Shorten intervals by 20%-30% (e.g., every 3 weeks instead of monthly).

Inspect Grease Condition – Remove old, contaminated grease to prevent lubrication failure.

3.Regular Cleaning & Inspection

Wipe Rails with a Lint-Free Cloth – Use alcohol or a dedicated rail cleaner to remove moisture and debris.

Check Slider Movement – Manually push the block to detect abnormal resistance or noise.

Inspect Seals – Ensure wipers and seals are intact to block moisture and dust.

4. Choose stainless steel products

As linear rail suppliers, NGS's stainless steel linear rail has absolutely advantages. stainless steel linear guides and stainless steel linear rail are ideal for humid, acidic, or saline environments (food processing, marine, medical applications).

5.Storage Tips for Long Downtime

If equipment remains idle during the rainy season:

Clean and coat rails with anti-rust oil

Wrap guides in moisture-proof paper or silica gel packs

Move sliders periodically to prevent localized rust

Frequently Asked Questions (FAQ)

As linear rail suppliers, We want to tell our customers while other linear rail suppliers may didn't tell you :

Q1: What if my linear guide already has rust?

A1: Light rust can be polished with fine sandpaper (1000+ grit) and treated with anti-rust oil. Severe rust may require rail replacement.

Q2: How often should I regrease guides in the rainy season?

A2: Reduce intervals by 20%-30%. For example, switch from monthly to every 3 weeks.

Q3: How do I know if my guides are affected by humidity?

A3: Look for water stains, thinning/emulsified grease, or unusual friction noises during operation.

Conclusion

High humidity during the rainy season threatens the performance and durability of linear guides. However, proactive measures—such as moisture protection, proper lubrication, and regular cleaning—can minimize damage and ensure smooth operation. Consistent maintenance reduces downtime and repair costs while maximizing guide lifespan.

Inspect your linear guides today and take action before the rainy season hits!