In modern industrial automation, high-load linear guides play a critical role. High precision linear guide rail not only provide high-precision, high-rigidity linear motion but also withstand heavy loads and high-speed operation, making high precision linear guide rail indispensable in CNC machines, industrial robots, semiconductor equipment, and more. This article explores the key features of high precision linear guide rail, cnc machine linear rail and showcases their outstanding performance across various industries through real-world case studies.

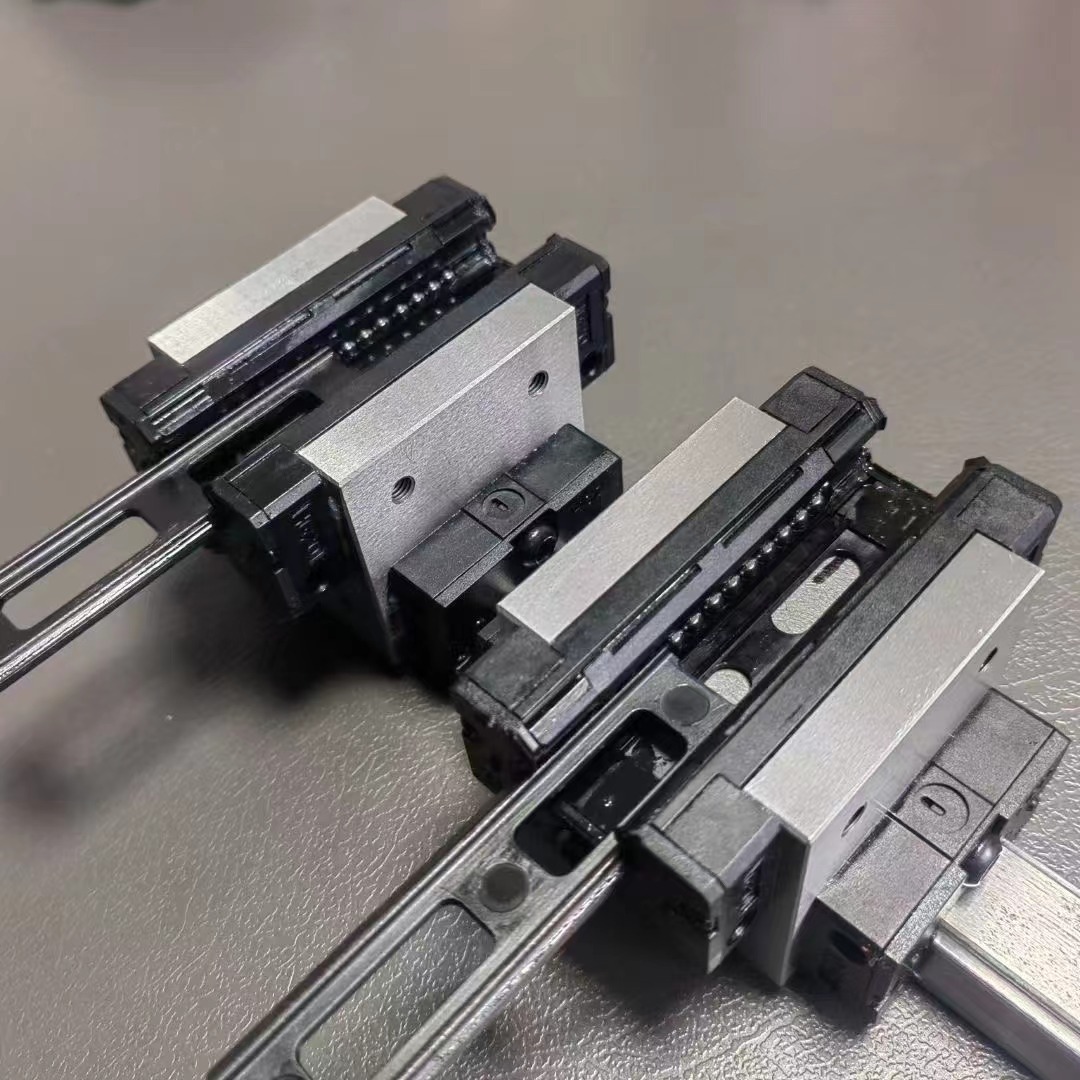

linear guide rail on the robot machine

linear guide rail on the robot machine

Core Advantages of High-Load Linear Guides

High-load high precision linear guide rail are the preferred choice for advanced manufacturing due to their exceptional characteristics:

1.1 Ultra-High Load Capacity

Four-row ball or roller design significantly increases load capacity, handling radial, reverse radial, and lateral forces. So cnc machine linear rail is suitable for machine.

High static stiffness makes them ideal for heavy cutting, stamping, and other high-intensity operations.

1.2 High Precision & Stability

Adjustable preload minimizes backlash, ensuring repeatability within ±0.005mm.

Low friction coefficient reduces energy loss and ensures smooth motion. So cnc machine linear rail is suitable for machine.

1.3 Long Lifespan & Low Maintenance

Sealed and dust-proof design prevents contamination from chips and debris, extending service life. So cnc machine linear rail is suitable for machine.

Self-lubricating sliders reduce manual maintenance needs. So cnc machine linear rail is suitable for machine.

1.4 Harsh Environment Resistance

Corrosion-resistant coatings (e.g., hard chrome plating, stainless steel) suit cleanroom environments (food, medical, semiconductor). So cnc machine linear rail is suitable for machine.

Stable performance in high-temperature, high-humidity, and high-vibration conditions.

High-Load Linear Guides in CNC Machines

CNC (Computer Numerical Control) machines are a classic application, especially in large gantry mills, turning-milling centers, and heavy-duty cutting machines.

2.1 Case Study: 5-Axis Machining Center

Challenge: When machining aerospace aluminum components, the machine must endure tons of cutting force while maintaining micron-level accuracy.

Solution: Roller-type cnc machine linear rail improve rigidity by 30% over traditional ball guides, with superior shock resistance. As a linear guide rail manufacturer, we recommend 25mm linear guide rail.

Result: Machining accuracy stabilized within 0.01mm, with 20% longer tool life.

2.2 Case Study: Heavy-Duty Lathe Z-Axis Feed System

Challenge: The Z-axis must handle high radial loads during large shaft machining without stick-slip.

Solution: Wide high-rigidity cnc machine linear rail, high precision linear guide rail + high preload sliders ensure smooth low-speed feed. As a linear guide rail manufacturer, we recommend 25mm linear guide rail.

Result: Surface roughness (Ra) improved to <0.8μm, with 15% higher productivity.

High-Load Linear Guides in Industrial Robots

Industrial robots demand speed, precision, and durability—critical for 6-axis robots, SCARA robots, and gantry manipulators.

3.1 Case Study: Automotive Welding Robot

Challenge: Welding arms must remain stable at >1m/s speeds while enduring frequent start-stop impacts.

Solution: Low-noise, high-acceleration guides + reinforced sliders minimize vibration. As a linear guide rail manufacturer, we recommend 25mm linear guide rail.25mm linear guide rail is very suitable.

Result: Repeatability of ±0.02mm, with MTBF >50,000 hours.

3.2 Case Study: Logistics Sorting Robot

Challenge: 24/7 operation under high-frequency, high-load conditions.

Solution: Self-lubricating guides + dust seals reduce maintenance.As a linear guide rail manufacturer, we recommend 25mm linear guide rail. 25mm linear guide rail is very suitable.

Result: Sorting speed reached 2,000 cycles/hour, with maintenance intervals extended to 1 year.

Other Industry Applications

4.1 Semiconductor: Wafer Handling Systems

Requires cleanroom-compatible, ultra-precise motion with zero backlash and particle-free operation.

Solution: Stainless steel guides + vacuum-rated design (Class 100 cleanroom). As a linear guide rail manufacturer, we recommend 25mm linear guide rail.

4.2 Medical: Surgical Robots

Needs vibration-free, ultra-smooth motion for precision surgery.

Solution: Silent guides + servo motor closed-loop control, positioning error <0.01mm.As a linear guide rail manufacturer, we recommend 25mm linear guide rail.

4.3 3D Printing: Large-Scale Metal Additive Manufacturing

Guides must support print heads in high-temperature environments.

Solution: Heat-resistant coating + forced-cooling sliders for long-term reliability.As a linear guide rail manufacturer, we recommend 25mm linear guide rail.

Future Trends: Smart & Lightweight Designs

With Industry 4.0, high-load linear guides are evolving toward smart and lightweight solutions:

Smart Guides: Integrated sensors monitor load, temperature, and vibration for predictive maintenance.

Composite Guides: Carbon fiber-reinforced structures reduce weight by 30% without sacrificing rigidity.

High-Speed Quiet Technology: Ideal for medical and lab environments.

Conclusion

High-load linear guides are the "invisible backbone" of advanced manufacturing, enabling precision in CNC machining and speed in robotics. Their rigidity, accuracy, and durability make them irreplaceable. As smart technology advances, they will continue driving industrial automation forward.

Need high-load linear guides for your equipment? Contact Us for customized solutions!