Linear guide rail is heavy duty linear slide rails designed by circular-arc groove and structure optimization are higher over 30% load capacity and rigidity than other similar ball type linear guideway. Heavy duty linear slide rails features the same load in four directions (up/down/right/left) and self-aligning to absorb installation-error capability.

Heavy duty linear slide rails is a high-precision motion system widely used in industry and machine building, specialised in scenarios where heavy loads need to be carried. Linear bearings and rails, the core components, ensure efficient, stable and precise linear motion. Linear slides heavy duty and linear guide rail reduce the coefficient of friction through the co-ordination of the linear slides heavy duty and the linear guide rail, which greatly improves the smoothness and precision of the movement.

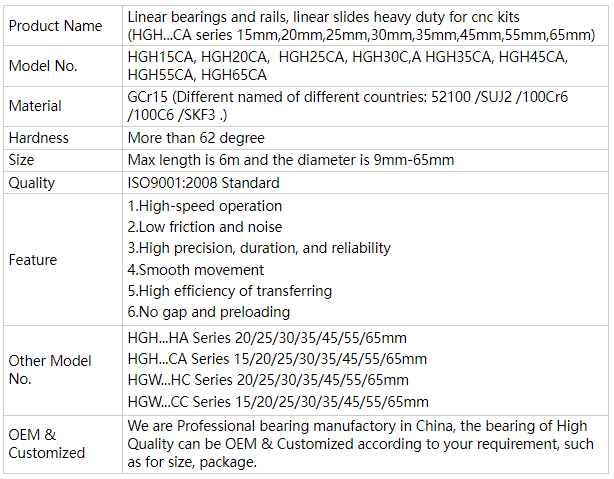

Linear guide rails are made from high strength materials, usually steel or aluminium alloys, to ensure high rigidity and corrosion resistance. In heavy duty applications, the rigidity and wear resistance of the linear guide rail is particularly important, because it needs to withstand a large amount of weight for a long time and maintain smooth operation. Heavy duty linear slide rails are designed for particularly high loads, and their linear slides heavy duty are often fitted with balls or rollers to ensure that linear slides heavy duty maintain low friction and high accuracy even under heavy loads.

Compared with ordinary linear bearings and rails, heavy-duty linear slide rails have a more robust structure and are able to support larger workloads, which is suitable for areas such as automation equipment, CNC machine tools, and large robotic arms. The design of the heavy duty slide rail system ensures precise positioning and smooth movement under high load conditions, which is particularly critical for some demanding manufacturing processes.

At NGS, we are committed to providing comprehensive after-sales support for ourheavy duty linear slide rails, linear bearings and rails. Our team of experts is available to assist you with any technical questions or issues you may encounter, ensuring that your equipment operates smoothly and efficiently. We offer a range of services, including installation guidance, maintenance tips, and troubleshooting assistance, all aimed at maximizing the longevity and performance of your linear guide rail systems. Additionally, we maintain a robust inventory of spare parts and can provide timely replacements to minimize downtime. Our goal is to ensure that you receive the highest level of support, from initial purchase to long-term operation, making your experience with NGS hassle-free and reliable.

Load capacity is determined by dynamic (C) and static (C₀) load ratings. For example: A 6205 deep groove ball bearing has a dynamic load rating of 14 kN, suitable for small motors. For heavy loads, choose tapered roller bearings (e.g., 32208 with C=90 kN). Recommendation: Share your equipment’s load analysis for optimal bearing selection.

Materials: Stainless steel (440C/316) or coatings (nickel plating, DLC). Seals: Double rubber seals (2RS) or PTFE seals. Example: Seawater pumps often use 316 stainless steel bearings with lifelong grease.

Speed limits depend on bearing type and lubrication: Standard 608ZZ ball bearings: ~18,000 rpm. Hybrid ceramic bearings (Si3N4 balls): 30–50% higher speeds. Solution: For high-speed applications, opt for oil lubrication or low-friction design.

Theoretical lifespan: Based on load calculations (see Q1). Real-world factors: Lubrication intervals (e.g., grease replenishment every 100km). Mounting surface flatness (≤0.01mm/m required). Tool: Free lifespan calculation software available.

Must-check: Slider hole spacing (e.g., 45mm×45mm). Rail width (15/20/25mm, etc.). Slider height (impacts machine space). Pro tip: Old slider model numbers are often engraved on the side.

Of course, we provide customized service, including add customers’ logo on the products, customized size of linear guide rail.

It according to the products, we usually can adjust the quantity according to customers’ request.

Invoices are automatically emailed to you when you complete your order. If you did not receive one contact us and provide your order number so we can find your order.

When your order ships you will receive an email with a tracking number which should have an estimated delivery date. Check your spam folder if you do not see it in your inbox. For more information on shipping, please reference our shipping policy.

You can either fill out the contact us form on our website, or head over to our sister website ngsbearing.com and request a quote over there for any product you see here on Bearings Direct. Please note that there will be minimum order quantities.