The rapid advancement of 3D printing technology has made high-precision, low-cost desktop printers increasingly popular. Among the many factors affecting print quality, the stability of the motion system is critical. SBR linear rails or sbr linear guide rail(Square Ball Rail) have become a preferred choice for many 3D printers due to their high rigidity, low friction, and cost-effectiveness. And sbr12, sbr16 rail,sbr20 linear rail are very suitable for 3D printer machines.

This article will explore:

✔ The role of SBR linear rail or SBR linear guide rail in 3D printers. Such as SBR12 .

✔ How to optimize SBR linear rail or SBR linear guide rail (Such as SBR12 .) for better print accuracy?

✔ Comparison of SBR linear rail or SBR linear guide rail with other linear motion solutions (e.g., linear guides, smooth rods)

✔ Common issues and maintenance tips

✔ Future trends in 3D printer rail technology

1

The Core Role of SBR Linear Rails in 3D Printers

1.1 What Are SBR Linear Rails?

SBR linear rails or SBR linear guide rail are a type of square-profile linear rail consisting of an aluminum or steel rail body and ball-bearing carriages. Key features include:

✅ High rigidity – Square design resists bending better than round rods. Such as SBR12, SBR16 rail, and SBR20 linear rail .

✅ Low friction – Ball-bearing recirculation ensures smooth motion. Such as SBR12 and SBR20 linear rail .

✅ Easy installation – Pre-assembled carriages make them ideal for DIY and budget machines. Such as SBR12, SBR16 rail, and SBR20 linear rail .

1.2 Why Do 3D Printers Need High-Precision Rails (Such as sbr12 .)?

Typical 3D printing layer heights range from 0.1–0.3mm. If the motion system is unstable, issues like the following may occur:

Layer shifting

Surface rippling artifacts

Dimensional inaccuracies

SBR linear rails or SBR linear guide rail minimize vibration and backlash, ensuring smooth movement of the print head (or build plate) for better print quality. Such as SBR12, SBR16 rail, and SBR20 linear rail .

2

Optimizing SBR Linear Rails(such as sbr12) for Higher 3D Printing Accuracy

2.1 Selecting the Right SBR linear Rail Model

Different SBR linear guide rail sizes suit different load and speed requirements:

HOW choosing between SBR12, SBR16 rail, and SBR20 linear rail ?

SBR12 : SBR12 is suitable for Small desktop printers 10-20kg X/Y-axis (print head) SBR12: Light-duty CNC machines . SBR12 delivers perfect performance at lower cost. SBR12 is easier to install and SBR12 provides excellent value.

SBR16 rail : SBR16 rail is suitable for Medium printers 20-40kg Z-axis (build plate)

SBR20 linear rail : SBR20 linear rail is suitable for Large industrial printers 40-80kg Heavy-duty frames .

Recommendations:

For print head movement (X/Y-axis), use SBR12 or SBR16 rail (lightweight).

For the Z-axis (vertical movement), use SBR16 rail or SBR20 linear rail (higher load capacity). While SBR16 rail works for Z-axis, many find the SBR12 sufficient for smaller printers when properly supported.

2.2 Proper Installation to Reduce Errors

Installation quality directly impacts print accuracy:

✅ Parallelism adjustment

✅ Preload adjustment

✅ Support reinforcement

2.3 Lubrication & Maintenance

Regular maintenance extends SBR rail lifespan:

Grease selection – Use PTFE grease for light loads, lithium grease for heavy loads.

Cleaning cycle – Clean and re-grease every 3 months to prevent dust buildup.

NGS as a professional linear rail manufacturer, our sbr12, sbr16 rail,sbr 20 linear rail are high quality. And our sbr12, sbr16 rail,sbr 20 linear rail are very suitable for 3D printer machines. SBR12 – Best for budget-friendly. SBR16 rail – The most versatile option. SBR20 linear rail – Designed for high-precision. By selecting the correct SBR linear rail—whether SBR12, SBR16 rail, or SBR20 linear rail—you ensure optimal performance.

3

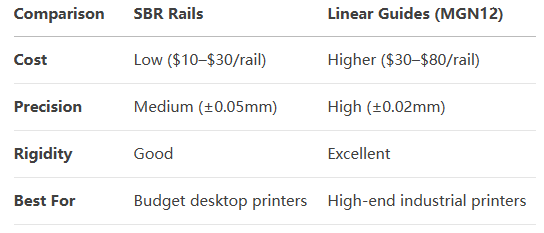

SBR Rails vs. Other Linear Motion Solutions

3.1 SBR Linear Rails (e.g., sbr12) vs. Linear Guides (e.g., MGN12)

3.2 SBR Rails vs. Smooth Rods (Round Rails)

Smooth rods (e.g., 8mm chrome-plated rods) are cheaper but prone to bending and wear, so sbr12,sbr16 rail and sbr 20 linear rail are suitable for high-speed printing.

4

Common Issues & Solutions

4.1 Layer Shifting?

Possible causes:

Loose rail screws → Re-tighten with threadlocker

Worn-out ball bearings → Replace carriage or entire rail

4.2 Noisy Rail Movement?

Insufficient lubrication → Clean and re-grease

Dust contamination → Install dust covers

5

Future Trends: The Evolution of 3D Printer Rails

Self-lubricating SBR rails (reduced maintenance) such as sbr12 and sbr16 rail.

Carbon fiber composite rails (lighter, stiffer)

Smart rails (wear sensors for predictive maintenance)

6

Conclusion

SBR rails offer an excellent balance of rigidity and affordability, making them (such as sbr12) ideal for desktop 3D printers. By selecting the right model, installing precisely, and maintaining regularly, print accuracy can be significantly improved. Future advancements in rail technology will further enhance 3D printing performance. sbr12 sbr12 sbr12 sbr12 sbr12 sbr12 sbr12

What type of rails does your 3D printer use? Share your experience in the comments!