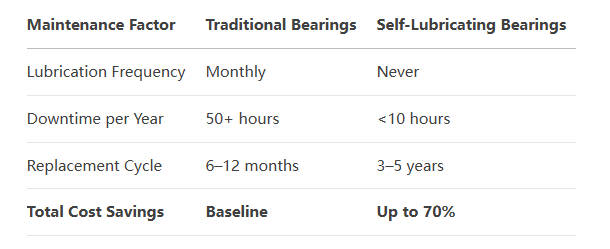

Self-Lubricating Joint Bearings Cut Maintenance Costs by 70%: The Future of Industrial Efficiency

In today's fast-paced industrial landscape, reducing downtime and maintenance costs is a top priority. Self-lubricating joint bearings or rod end ball joint have emerged as a game-changing solution, offering up to 70% lower maintenance costs compared to traditional bearings. These innovative rod end ball joint or female rod end bearing are transforming industries from automotive manufacturing to renewable energy, delivering unmatched reliability and efficiency.

How Self-Lubricating joint bearings or rod end ball joint Work

Unlike conventional bearings that require regular greasing, self-lubricating joint bearings integrate solid lubricants (such as PTFE, graphite, or MoS₂) into their sliding layers. This design of joint bearings ensure:

✔ Continuous lubrication – No need for manual re-greasing

✔ Reduced friction – Coefficient as low as 0.05–0.10

✔ Longer service life – Up to 3–5x longer than standard bearings

✔ Contamination resistance – Ideal for dirty or wet environments

Industries Benefiting the Most

1. Heavy Machinery & Construction

Excavators, cranes, and mining equipment experience 40% less wear with self-lubricating joint bearings (rod end ball joint and female rod end bearing ).

Case Study: A German mining company use self-lubricating joint bearings (rod end ball joint and female rod end bearing ), such as 1 4 20 female rod end, 5 16 rod end ball joint, which reduced bearing replacements from quarterly to once every 2 years.

2. Automotive & Robotics

Self-lubricating joint bearings (rod end ball joint and female rod end bearing ) Used in suspension systems, steering linkages, and robotic arms.

Tesla’s Gigafactories report 30% fewer maintenance stops after switching to self-lubricating bearings, such as 1 4 20 female rod end, 5 16 rod end ball joint.

3. Marine & Offshore Applications

Saltwater corrosion? No problem. These bearings withstand harsh marine conditions without degradation.

Cost Savings Breakdown

female rod end bearing : 1 4 20 female rod end

Key Specifications of 1 4 20 female rod end:

Thread: 1/4"-20 UNF (Unified Fine Thread, 20 TPI)

Gender: Female (internal threads)

Type: Spherical plain bearing / rolling element

Load Capacity of 1 4 20 female rod end:

Dynamic Radial: ~500 kg

Dynamic Axial: ~200 kg

Materials of 1 4 20 female rod end:

Body: Carbon steel (zinc-plated) / Stainless steel (304/316)

Ball: Chrome steel (HRC 58-62)

Sealing: Rubber seals or PTFE-lined (maintenance-free option)

Typical Applications

Precision mechanisms: 3D printer linkages, RC vehicle steering

Industrial automation: Conveyor belt adjusters, sensor mounts

Automotive: Throttle linkages, suspension tuning

Advantages

✔ Fine adjustment: 0.05mm-level precision with UNF threads

✔ Compact: Total length typically <40mm

✔ Corrosion-resistant: 316SS version for harsh environments

joint bearings : 5 16 rod end ball joint

Key Specifications of 5 16 rod end ball joint:

Thread: 5/16"-24 UNF (or 5/16"-18 UNC)

Gender: Male (external threads) standard (female available)

Design: Ball-and-socket joint (±25° articulation)

Load Capacity of 5 16 rod end ball joint:

Dynamic Radial: ~800 kg

Dynamic Axial: ~350 kg

Materials of 5 16 rod end ball joint:

Ball: Alloy steel (hardened & ground)

Housing: Forged steel / Aerospace aluminum (lightweight)

Temperature: -30°C to +120°C (high-temp versions to 250°C)

Typical Applications

Heavy equipment: Tractor suspension, hydraulic cylinders

Aerospace: Flight control linkages (MIL-SPEC compliant)

Motorsports: Shift mechanisms, push-rod suspensions

Advantages of female rod end bearing

✔ High rigidity: Forged housing withstands 50% more shock loads

✔ Misalignment compensation: Tolerates ±3° shaft deflection

✔ Modular: Replaceable ball head without full disassembly