Guide rails are critical components in CNC machines, 3D printers, automation systems, and industrial equipment. Over time, wear and tear can reduce their precision, leading to costly downtime and poor product quality. Recognizing the early signs of failing guide rails can save thousands in repair costs and prevent machine breakdowns.

1. Visible Wear & Physical Damage

1.1 Scratches, Dents, and Pitting

Cause: Contaminants (dust, metal chips), improper lubrication, or misalignment.

Effect: Increased friction, jerky motion, and reduced accuracy.

Solution: If damage exceeds 0.05mm depth, replacement is recommended.

1.2 Corrosion & Rust

Cause: Exposure to moisture, coolants, or harsh chemicals.

Effect: Stiff movement, increased wear on bearings.

Solution: Stainless steel or coated rails may be needed in humid environments.

2. Abnormal Noises During Operation

2.1 Grinding or Squeaking Sounds

Cause: Lack of lubrication, ball bearing damage, or rail deformation.

Effect: Accelerated wear on the recirculating balls.

Solution: Relubricate first. If noise persists, inspect bearings.

2.2 Clicking or Knocking Noises

Cause: Worn-out ball bearings or cracked rail tracks.

Effect: Vibration transfer to machined parts, reducing finish quality.

Solution: Replace the linear guide block or entire rail assembly.

3. Reduced Precision & Machine Vibration

3.1 Increased Backlash & Play

Cause: Worn ball grooves or loose preload.

Effect: Poor repeatability (±0.1mm or worse).

Solution: Check preload adjustment. If play remains, replace the rail.

3.2 Uneven Movement or Stick-Slip Effect

Cause: Contaminated rails, damaged seals, or lubrication failure.

Effect: Jerky motion, affecting CNC cutting accuracy.

Solution: Clean and relubricate. If problem persists, replace.

4. Excessive Heat Generation

4.1 Overheating in High-Speed Applications

Cause: Friction from misalignment, poor lubrication, or overload.

Effect: Thermal expansion leads to further misalignment.

Solution: Check alignment and load capacity. As linear guide manufacturers, we want to say -Upgrade to high-speed-rated rails if needed.

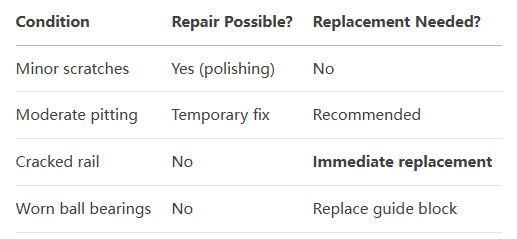

5. When to Repair vs. Replace

Cost Consideration:

Repairing may cost 30-50% of a new rail, but lifespan is shorter.

Replacing ensures long-term reliability and warranty coverage.

6. Best Replacement Practices

6.1 Choosing the Right Rail

For CNC Machines: high precision linear guide from professional linear guide manufacturers-such as HIWIN,NGS,THK. For example, NGS hgh20.

For 3D Printers: IGUS polymer rails (low noise), high precision linear guide from professional linear guide manufacturers-such as HIWIN,NGS,THK. For example, NGS hgh20.

For Heavy Loads: oversized guide rails, high precision linear guide from professional linear guide manufacturers-such as HIWIN,NGS,THK. For example, NGS hgh20.

6.2 Installation Tips

✔ Use a granite surface plate for alignment verification.

✔ Torque bolts evenly to avoid rail distortion.

✔ Apply lithium-based grease before operation.

High precision linear guide hgh20 from linear guide manufacturers

NGS hgh20 High precision linear guide and hgh20 block

hgh20 is suitable for cnc equipment, wood machine equipment, logistic equipment and so on.

width of hgh20: 20mm, high of hgh20: 17.5mm, longth of hgh20 : 4000mm ( longth can be customized )

The weight of hgh20 rail is 2.21kg/m , The weight of hgh20 block is 0.3kg/pcs, hgh20's screw is M5*16

we provide OEM and ODM service for hgh20 rail and hgh20 block

NGS hgh20 block have many colors, black, green, blue.

Block of hgh20 rail : HGH20 CA, HGH20 HA, HGH20 CC,HGH20 HC

If you want know more about NGS hgh20 rail and hgh20 block, please contact us!