Why Choose Polymer Linear Bearings Over Metal?

--Low Noise & Self-Lubricating Benefits

In the world of linear motion systems, bearings play a critical role in ensuring smooth movement, reducing friction, and extending equipment lifespan. While metal linear bearings have traditionally dominated the market, engineering polymer linear bearings (Plastic linear bearings ) are rapidly gaining popularity due to Plastic linear bearings’ unique advantages—particularly in applications where noise reduction, self-lubrication, and corrosion resistance are essential.

This in-depth guide explores:

✔ Key differences between polymer and metal linear bearings

✔ Top benefits of polymer bearings (low noise, self-lubrication, corrosion resistance, etc.)

✔ Industries best suited for plastic linear bearings

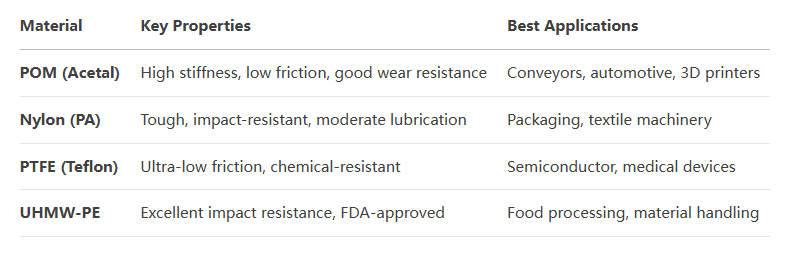

✔ Common materials (POM, Nylon, PTFE, UHMW-PE) and their properties

✔ Real-world applications and case studies

✔ Maintenance and cost comparisons

By the end, you’ll understand why many engineers and linear bearing manufacturer are switching to polymer linear bearings for improved performance and efficiency.

Polymer vs. Metal Linear Bearings: Key Differences

NGS as a professional linear bearing manufacturer, we'd like to introduce:

1.1 Material Composition

Metal Bearings: Typically made from steel, stainless steel, or bronze. Require external lubrication (oil/grease).

Polymer linear bearings : Made from engineering plastics like POM (Acetal), Nylon (PA), PTFE, or UHMW-PE. Often self-lubricating.

1.2 Friction & Wear Resistance

Metal Bearings: High friction without lubrication, leading to wear over time.

Polymer linear bearings: Naturally low friction, reducing wear even in dry conditions.

1.3 Noise Levels

Metal Bearings: Can generate significant noise, especially in high-speed applications.

Plastic linear bearings: Absorb vibrations, resulting in quieter operation (ideal for medical, packaging, and office equipment).

1.4 Corrosion Resistance

Metal Bearings: Prone to rust in humid or chemical environments unless stainless steel is used (higher cost).

Plastic linear bearings: Immune to rust and resistant to many chemicals, making them perfect for food processing, marine, and chemical industries.

Top Benefits of Polymer Linear Bearings

NGS as a professional linear bearing manufacturer, we'd like to introduce:

2.1 Low Noise & Vibration Damping

Polymer bearings significantly reduce operational noise, making them ideal for:

✅ Medical devices (MRI machines, surgical robots)

✅ Office automation (printers, scanners)

✅ Packaging machinery (where noise reduction improves workplace conditions)

Example: A packaging company reduced noise levels by 40% after switching from steel to POM linear bearings.

2.2 Self-Lubricating Properties

NGS as a professional linear bearing manufacturer, we'd like to introduce:Unlike metal bearings, many polymer bearings contain embedded lubricants (PTFE, graphite, or oil-filled resins), eliminating the need for external lubrication. Benefits include:

✔ Reduced maintenance costs

✔ No grease contamination (critical in food & pharma industries)

✔ Better performance in dusty/dirty environments

2.3 Corrosion & Chemical Resistance

Polymer bearings excel in harsh environments:

Food & Beverage: Resistant to washdowns and cleaning chemicals.

Marine Applications: No rust in saltwater conditions.

Chemical Processing: Withstand acids, alkalis, and solvents.

2.4 Lightweight & Energy Efficient

Plastic bearings are up to 80% lighter than metal equivalents, reducing inertia and energy consumption in automated systems.

2.5 Cost-Effectiveness

While high-performance polymers may have a higher initial cost than basic steel bearings, they often save money long-term due to:

✔ No lubrication costs

✔ Reduced downtime

✔ Longer lifespan in corrosive environments

Best Polymer Materials for Linear Bearings

NGS as a professional linear bearing manufacturer, we'd like to introduce:

Real-World Applications

4.1 Food & Beverage Industry

Problem: Stainless steel bearings require frequent lubrication, risking contamination.

Solution: UHMW-PE bearings provide FDA-compliant, self-lubricating performance.

4.2 Medical & Laboratory Equipment

Problem: Metal bearings can corrode from disinfectants.

Solution: PTFE-coated bearings ensure smooth, maintenance-free operation.

4.3 Packaging Machinery

Problem: Noisy operation affects worker comfort.

Solution: POM bearings reduce noise while maintaining precision.

Maintenance & Longevity

NGS as a professional linear bearing manufacturer, we'd like to introduce:

Metal Bearings: Require regular lubrication; prone to seizing if neglected.

Polymer Bearings: Often maintenance-free, with longer service life in corrosive/dry environments.

Conclusion: Should You Switch to Polymer Linear Bearings?

Polymer linear bearings offer lower noise, self-lubrication, corrosion resistance, and reduced maintenance—making them superior to metal in many applications. While they may not replace heavy-duty steel bearings in extreme load scenarios, they are an excellent choice for industries like food processing, medical, packaging, and automation.

Ready to upgrade? Explore our range of high-performance polymer linear bearings designed for durability and efficiency!